Dear All,

All of our screens are ok, and the smudging is due to paper and screen being too tight and too flushed together when printing.

I have gone to a supplier- and they confirmed our screens are ok.

The issue of smudge is the way we print- there are few small steps when printing that we should do.

Please note that next week we will be printing in class using the same screens from this week

- If anyone would want to do a new design for tote bag- you are more than welcome. We have enough chemical for re-coating and re-exposing the same screens. But each new design would need new transparencies (doubled up the same transparency with the same image; ensure that the image is solid opaque black and white or halftone for gray -no Gray values!) Any gray on your screen will NOT expose only black and white. Chemical reacts with light and hardens on white creating negative stencil; Black protects your image resulting that the chemical does not react with light- allowing to dissolve with washing leaving a positive stencil – the image you want

- Too fine detail might not develop- but the best is to try

- Whoever wants to print the old design and reuse the same screen to do new design- also can. The screen can be reclaimed – by washing and new design can be done during class.

- In regards to the image for transparencies:

It has to be solid opaque black and white image (with halftone for gray) and NO Gray values or shades :

PLEASE point to online tutorials ( in project Brief 2 Forrest Gump)

https://oss.adm.ntu.edu.sg/2016-dn1002–g7/syllabus/project-2/#1473078213010

https://www.youtube.com/watch?v=usDDwwraaRk

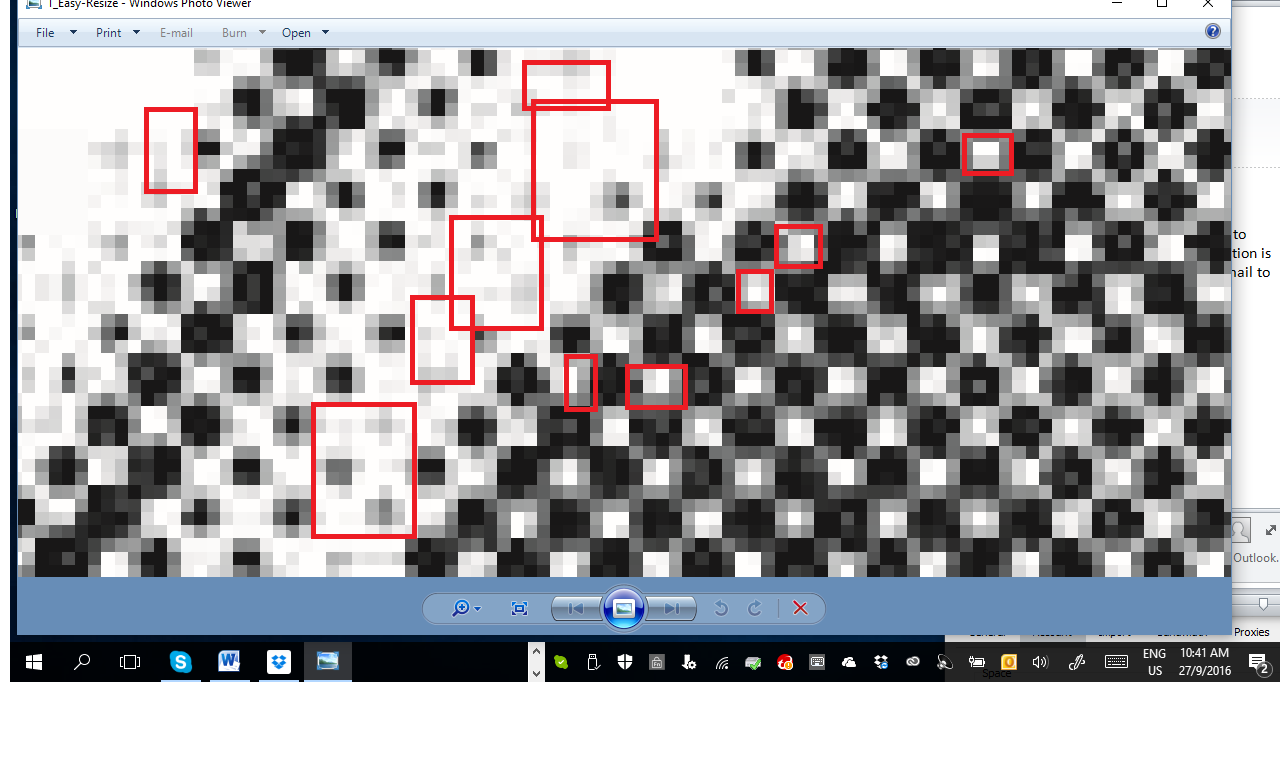

https://www.youtube.com/watch?v=uFjaMVnGzGA - If you Zoom into your image and see grayscale you need to redo. Below image is still NOT half tone- THIS IS the problem few people have. There are still gray values and no half-tone for gray.

For resolution- I have RE- attached handout from the OSS on how to get HR image Google_Search_HR_images

If you are not sure please let me know and email me image

Thank You so much!

See you next Monday

1 Comment