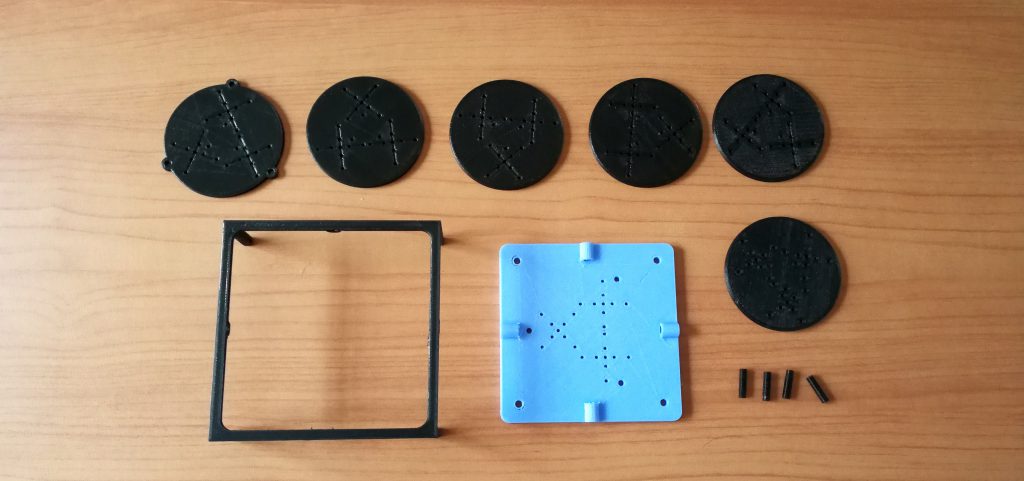

Printed

Here are the printed parts ready for testing. The base is blue so that the distinction from the base and the spring set up is easier to identify for video documentation. There are a total of 6 circle plates that would make the main moving body. The 4 small cylinders are use to anchor the base in place when attaching to the frame.

Assembly (spring to plate)

I bought some metal wires to attach this spring to the plate. I need to buy thinner wires as this thickness of wire is very hard to work with. I think it is 0.5mm.

It took me 2 hours and a bruised palm just to attach all of them together. Use a total of 6 plates and 18 springs. Note: Should have designed the holes a little bit bigger.

Testing the spring

One unit of it is very bouncy. Now I have to put them all together which will use another 2 hours to do so. And again, working with the thick wires is extremely hard as the wires are hard to bend and maneuver when I want to secure the ends of the wire between the springs

Assembly (spring to spring to base)

Finally I assembled the entire set up. As seen, the set up is tilted towards one side. I am thinking that there is not enough distance between springs. The set up also cant stand up properly. Overall, there are 3 things to change for the next model.

Firstly, the distance between the springs has to be further.

Secondly, there should be 4 springs instead of 3 as it will help the set up to stand on its own.

Lastly, the holes on the plate should be bigger as it was very hard to attach everything together.