The Water Dress

Introduction

The concept was derived from the shrinking resources for clean, drinkable water. I wanted to design a dress that could bring awareness of this issue as well as provide some sort of solution to it. I was able to achieve both goals by using a skirt that is built up of drop-shaped plastic to indicate water; and by using a built in water filter to produce drinkable water on the spot. There are additional LED lights attached to the skirt that light in water flowing motion with white and blue colors.

Topic B

Today’s world is facing numerous environmental threats. Ranging from water pollution to global warming, each threat impacts our society in a challenging way. The consequences of water pollution and the shrinking resources to pure water could be especially devastating. Water is an everyday essential for humans. In some places of the world war could start over clean water resources. In other places, humans are fighting with diseases from drinking contaminated water (Niveen Tadros, 1997). Some nations are zealously experimenting to purify water using modern technology. It is of utmost importance that the young and old are educated about such issues, as well as collaborate to make a better future.

I intended to raise awareness to these issues as well as use modern research to find a solution. The theme of water drop appears in several forms on the dress, more specifically the skirt and the attachable filter with the pouches. The overall color of white also suggests cleanliness and purity. The lights of blue and white also imitate water. The solution comes in a form of a water filter. The main ingredient is activated charcoal. It can eliminate or reduce chemicals and substances that are harmful for human consumption (all-about-water-filters.com). Thus, the method can be applicable for campers to purify water from puddles, for people who do not have access to water to collect and purify rain water, or for refugees to purify tap water.

Mechanics

Top piece

To make it easy to wear I wanted to make each piece stand-alone in itself. I chose a simple, white cotton fabric for the top so that it would not dominate the overall look. I designed it to be sleeveless to make it easier to put together but also to focus the attention on a vertical level. Originally I thought to make it hip-length but when Galina saw my bottom piece, which was quite transparent, she suggested that I make it longer to around mid-leg. She also had a vintage dress template with a princess cut so I just used it to make the top piece. As the fabric is not a stretching material, the back has a zipper line to make it possible to wear without tearing the dress. When my model first tried the dress on there seemed to be some extra fabric under the breast line so we decided to add bra cups to the front that would flatten out the dress a little more. There are two attachable side pockets on each bottom side of the dress to store the electronics. The end product is a simple and elegant white dress.

Bottom piece

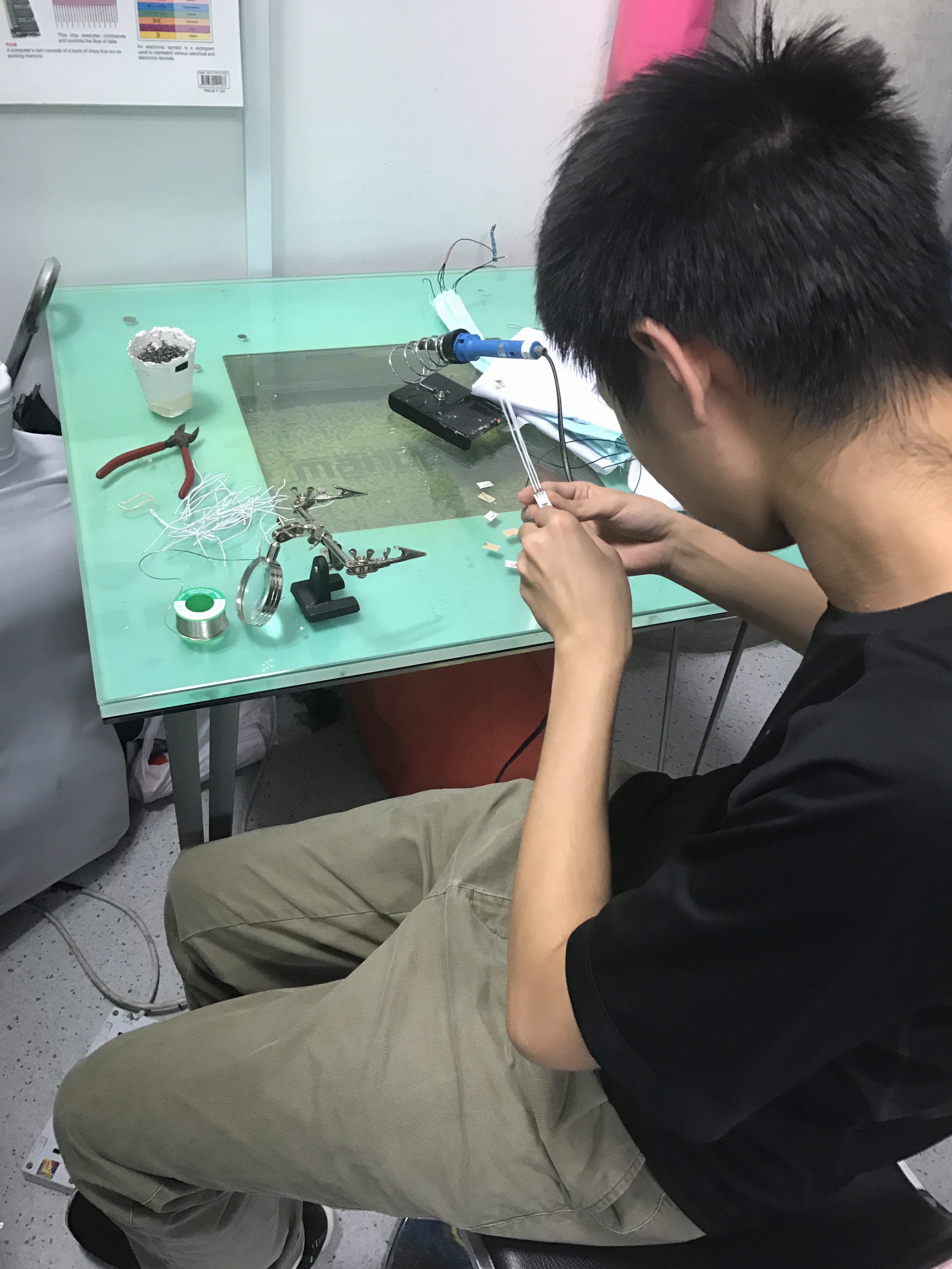

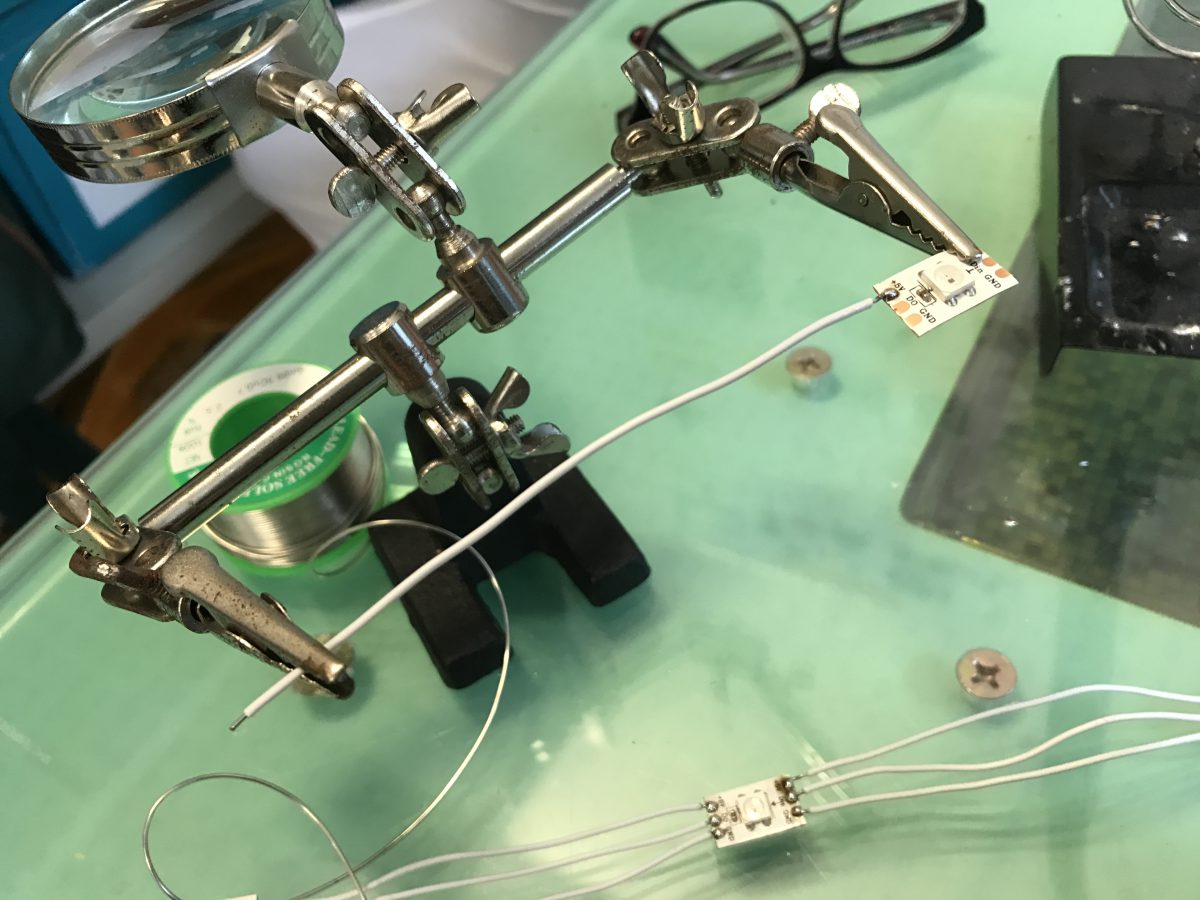

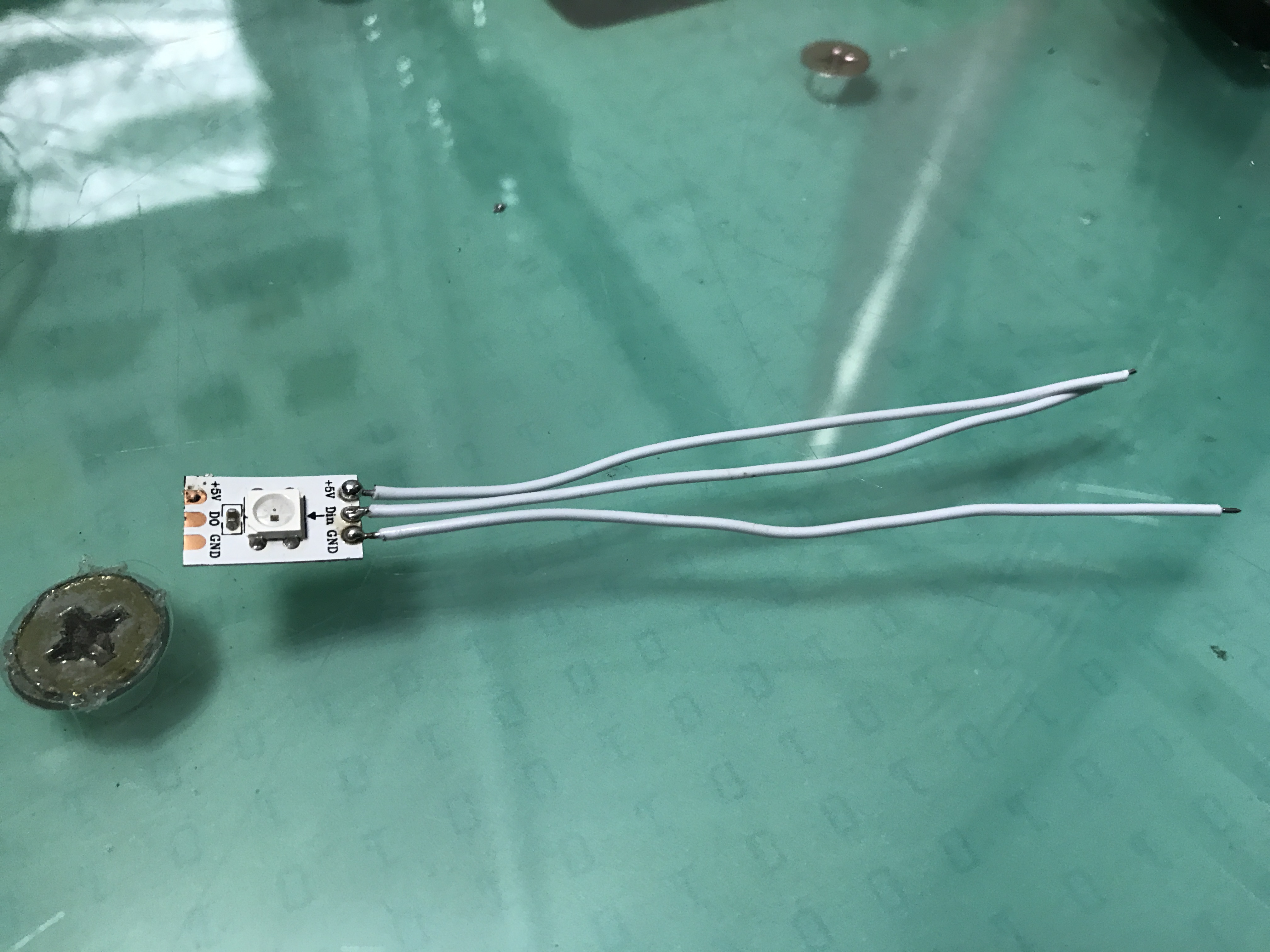

I chose to use plastic as my material for the bottom piece. I wanted to use this inexpensive material to bring attention to recycling and the waste of plastic that is causing contamination in many water supplies (lake, ocean). Initially I designed the bottom piece to be a layer of infused plastic only. I infused 3 layers of plastic bags but it turned out quite unpolished as I was unable to iron the material to become flat and consistent. In the meantime I started experimenting with my droplet pouches so Galina and I both agreed that it would be nice to cover the whole skirt with the droplets. That is when the ‘real’ production started as I had to make more than 300 droplets infusing plastic bags and cutting them out by hand. However, the outcome looked quite fabulous. There are also 8 LED light strips (each strip with 8 lights) attached to the skirt from the inside. It was a tedious work to solder the strips together with precut-length wires but with help of my very nice friend it was possible. My friend also helped me program the Lilypad so that the lights turned on to imitate water flow with blue and white colors. The lights were connected a switch, which activated the Lilypad to start the lights and it was powered from a power bank. To make it easier to wear, there is an opening at the back of the skirt which can be closed with velcro tapes.

Refer to video: LED lights (semi-dark) and LED lights (dark)

Attachable Water Filter piece

The visible water filter consists of three main parts: container, filter, and pouches. The container was a regular transparent water bottle, which can contain about 330ml of water and it was put on the back of the model. The container is attached with tubes to the filter pouch (containing activated carbon) which is at the front of the model on the chest. The filter pouch is made of two layers of clear plastic infused only at the outer edges as there is a small pouch of white fabric that holds the charcoal. The fabric of the cotton allows water to flow out from it into the plastic. There are three hanging droplet shaped plastic pouches attached to the bottom of the filter to collect the dripping water. There is a water pump hidden below the skirt, powered with batteries, and it can be activated with a switch. Once the switch is turned on, the water pump sucks air from the container so the inserted tubes will be filled with water that would flow to the front filter pouch. As the water flows through the filter, it becomes purified, and flows into the droplet shaped pouches. These pouches can be removed from the filter and using the straw on the top and water can be drank directly from the pouches. After drinking, the pouches can be reattached to the filter.

Refer to video: Water pump mechanics

Final Product

Refer to video: The Water Dress (close up) and The Water Dress (walk)