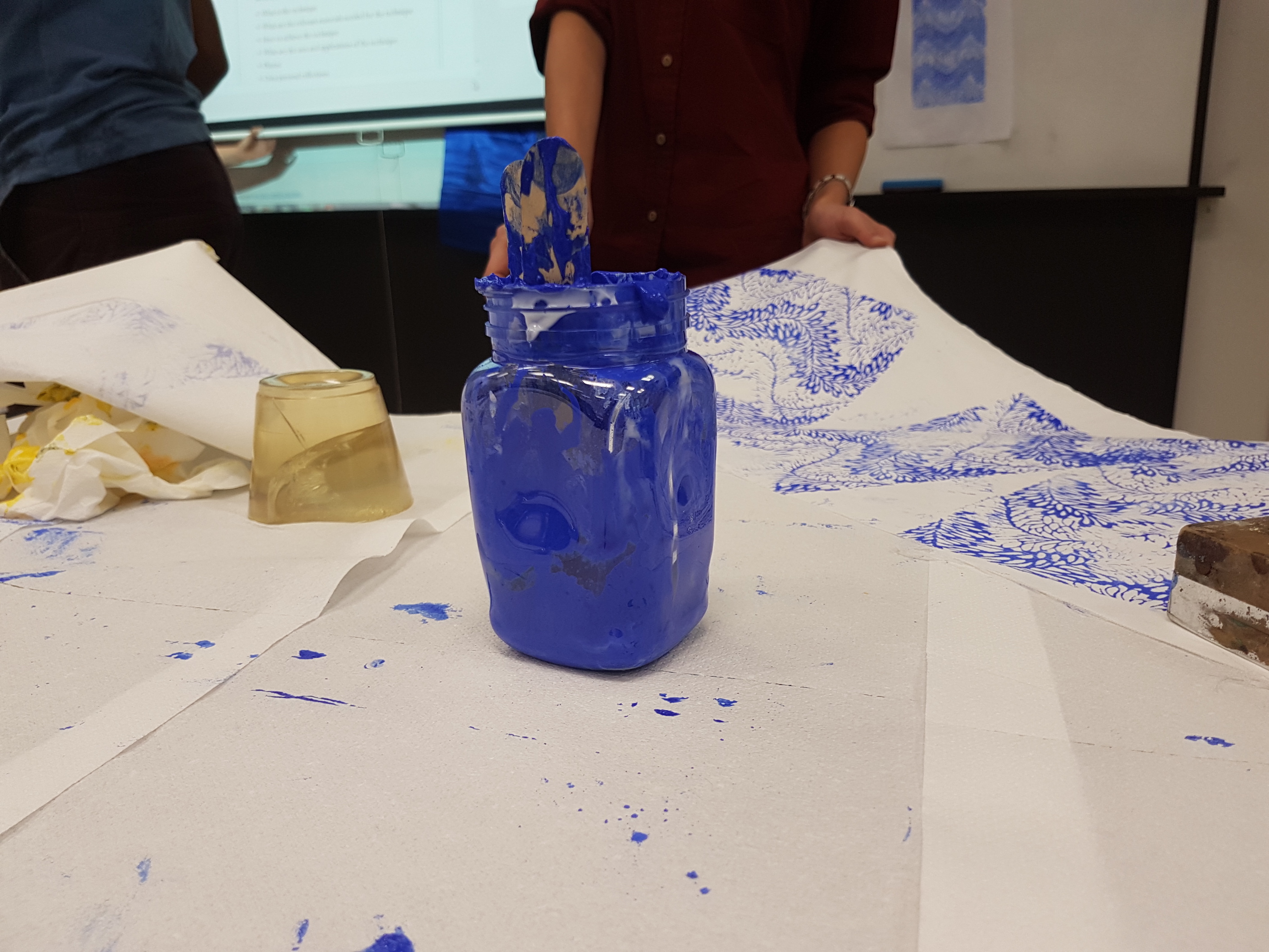

This week we visited Touch & Print at Waterloo Centre and learned about transfer printing techniques and their applications.

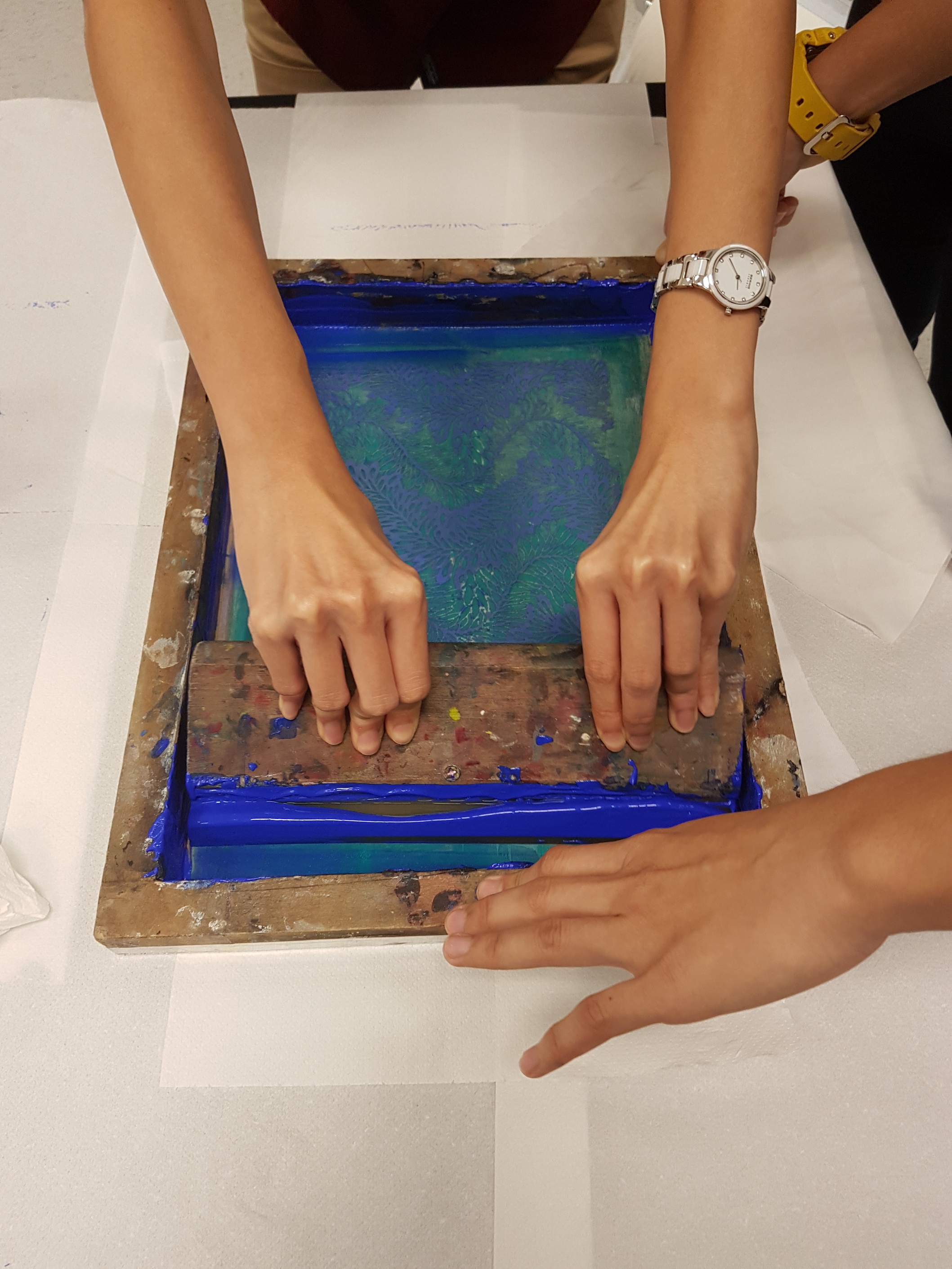

Leon explained the pros and cons of various techniques, such as how screen printing is used for mass production, where despite the long setup process, each reprint is fast and inexpensive. He also illustrated the different printing techniques, how they can achieve different effects on a variety of materials such as fabric, wood and metal.

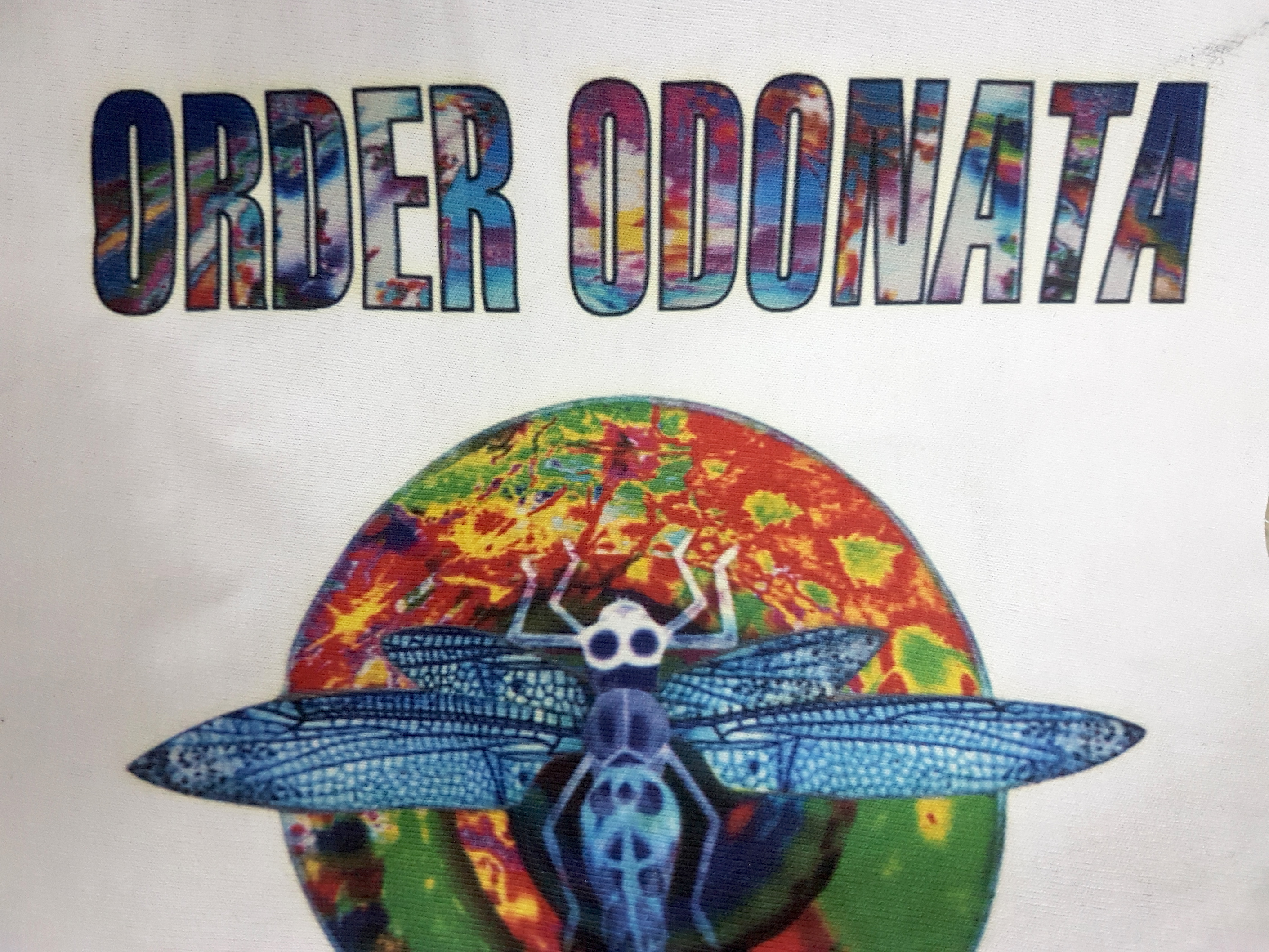

He showed how printing on white often left a film border around the image, and how laser cutting could eliminated the border to create a more seamless result.

Previously, I never really considered how printing techniques affected the overall quality of product, e.g. the film border of an image or how thick and stiff the printed portion became. The care and thought that go into these printing techniques made me consider these differences in quality between a cheap T-shirt and one made using more suitable printing techniques.

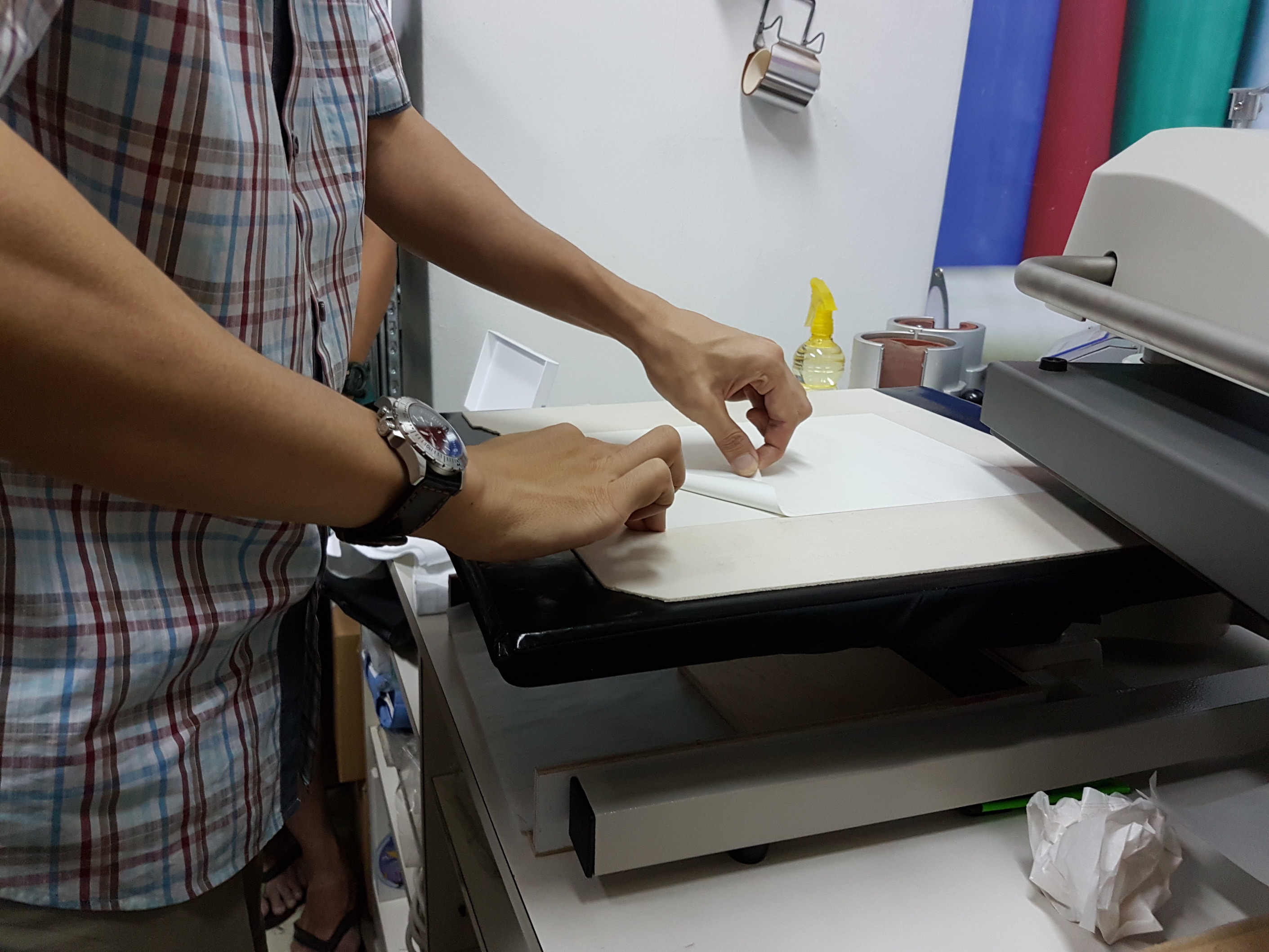

He also gave live demonstrations and explained how printing white on dark backgrounds required further steps such as the use of white toner.

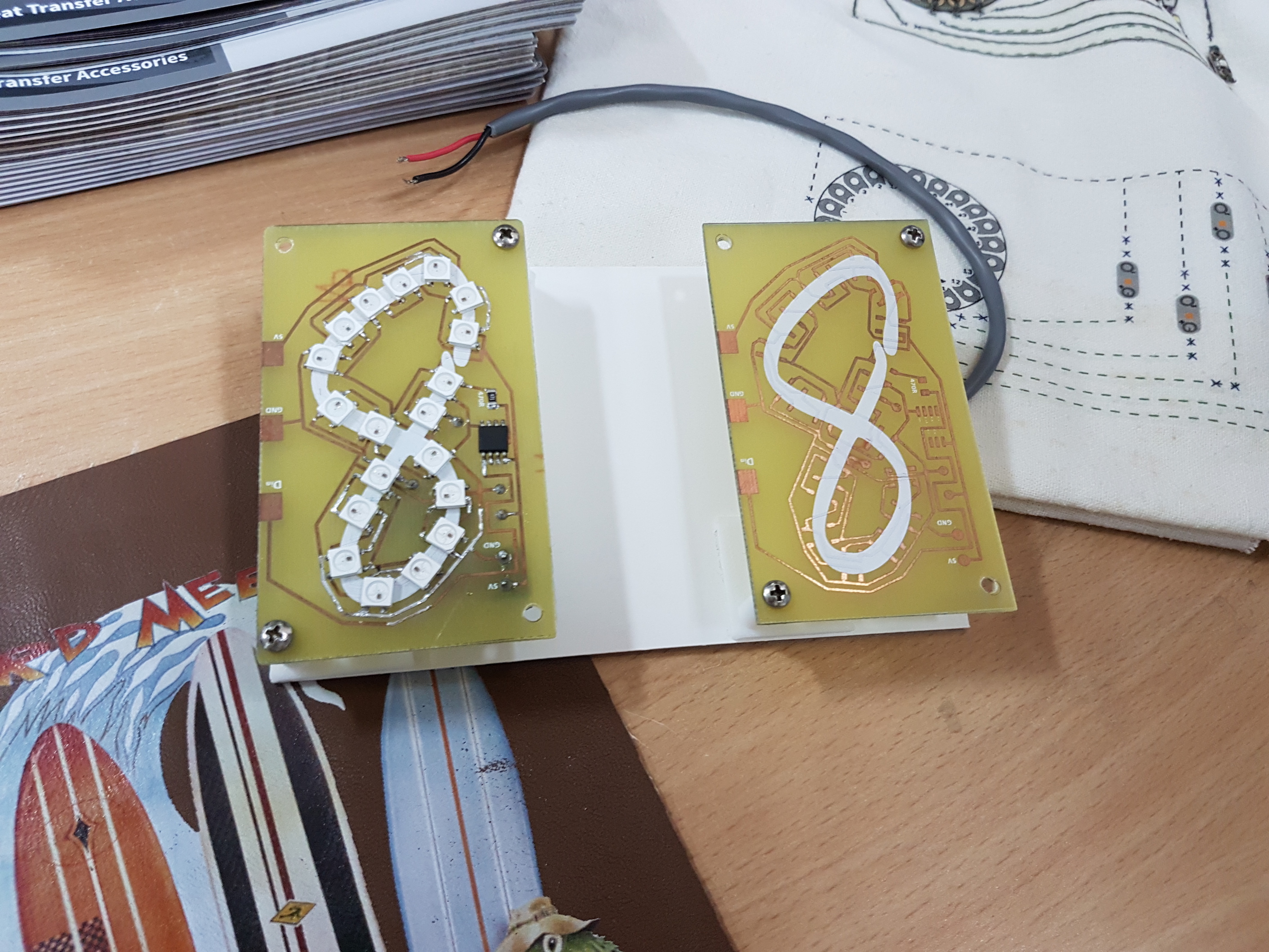

The alternative uses of printing techniques was very interesting and I never knew it could be applied together with etching to create interactive components such as custom circuit boards!