There are many different types of materials for 3D printing, each has its owe characteristics, pros and cons. Here are some of the more common options:

reference: blog.tinkercad.com

last access 15th Oct 2016

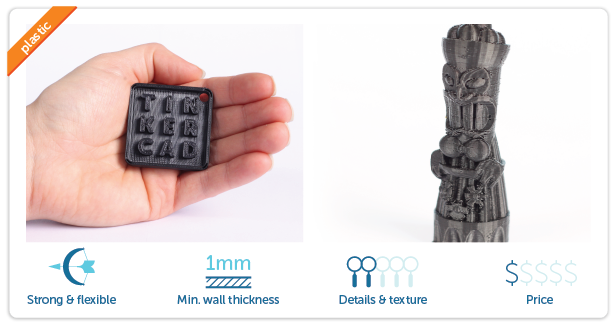

Nylon:(Polyamide)

-Also called White, strong & flexible/ Durable plastic/ White plastic

-Strong and flexible plastic

-1mm minimum wall thickness

-Naturally white, but you can get it colored

-About 10 layers per 1mm

-Made from powder

-Alumide=Polyamide + Aluminum

-Interlocking, moving parts possible

last access 15th Oct 2016

ABS:(Home printers)

-Strong plastic like legos are

-Made from spaghetti like filament

-Many color options

-about 3 layers per 1mm

-1mm minimum wall thickness

last access 15th Oct 2016

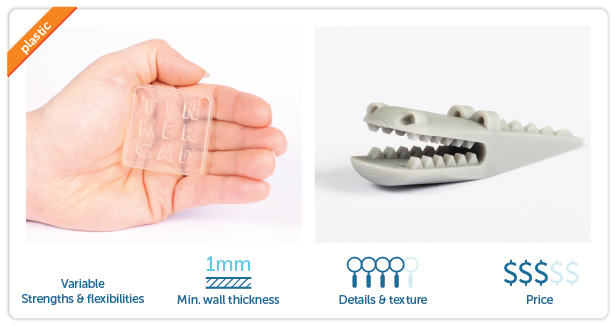

Resin:(Multiple options)

-Also called White resin, Black resin, Transparent detail/ White deail resin/ High detail resin, Transparent resin, Paintable Resin

-Rigid and a bit delicate

-Liquid Photopolymer cured with UV light

-White, black & transparent most typical colors

-About 10 layers per 1mm

-1mm minimum wall thickness

last access 15th Oct 2016

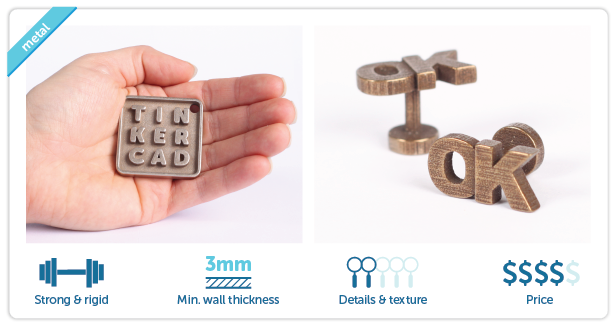

Stainless Steel:

-Very strong material

-Made with multiple steps or from powder directly

-Coloring options like gold and bronze plating

-About 6 layers per 1mm

-3mm minimum wall thickness

15th Oct 2016

Gold & Silver

-Strong materials

-Made from wax and then casted/processed in powder form

-About 10 layers per 1mm

–0.5mm minimum wall thickness

last access 15th Oct 2016

Titanium:

-Strongest material

-Direct metal laser sintering

-About 30 layers per 1mm

-o.2mm minimum wall thickness

*note: sintering is the process of compacting and forming a solid mass of material by heating or pressure without melting it to the point of liquefaction(lose strength and behave like a liquid). Sintering happens naturally in mineral deposits or as a manufacturing process used with metals, ceramics, plastics, and other materials.

last access 15th Oct 2016

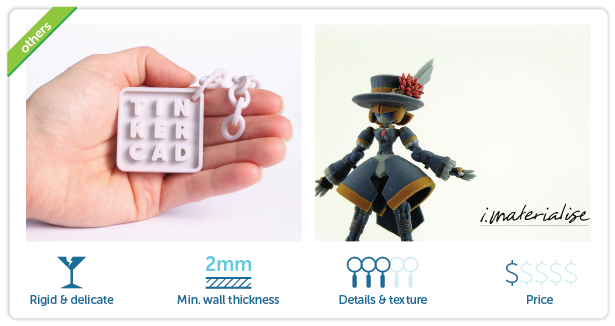

Ceramic:

-Rigid & delicate

-First ceramic is printed then surface is glazed

-Ceramic White, glaze typically white

-About 6 layers per 1mm

-3mm minimum wall thickness

-After printing , firing and glazing is still required

last access 15th Oct 2016

Gypsum:

-Also called Sandstone/ Rainbow ceramics/ Multicolor

-Rigid & delicate made from powder

-Naturally white, but you can get it with colors

-About 10 layers per 1mm

-2mm minimum wall thickness

Other materials includes Laywood, PLA, Aluminium and Cobalt derivstives(industrial grade 3D printing), and even paper.

For my jewelry product, it is obvious that metals are the best material for the appearance. They are strong and can be made into intricate designs as the minimum thickness is comparably small, and the layers per 1mm is comparably large.

However, in ADM, metal 3D printing is currently unavailable. As such, I would carry out my modelling in alternative material available that is best suitable to present my design.

Another aspect is the cost of the printing. Using silver and gold can be costly, and resulting in the high retail price of the product. Stainless steel is lower in cost, but the product would be more rigid.

CNC is also possible. As far as I know, ADM have metal cnc.