According to Singapore’s law, an inflatable which is characteristic of the below is considered an amusement park.

- An inflatable which a patron may enter upon or within or climb on:

- which has any enclosed space that is fully or partially roofed over or covered, the base of which enclosed space occupies an area equal to or exceeding 30 square metres;

- which has any enclosed space that is fully or partially roofed over or covered of any size, within which the maximum vertical displacement of a patron using the inflatable is equal to or exceeds 5 metres; or

- the base of which occupies an area equal to or exceeding 150 square metres, whether or not the inflatable has any enclosed space

Hence it has to adhere to structural & mechanical and process guidelines and is required to be assessed and certified by a qualified person (QP), who is a specialist professional engineer, registered in the discipline of amusement ride engineering with the Professional Engineers Board.

Quoting the same website,

“For a major amusement ride with a higher risk and safety profile, the qualifed person will be required to engage and consider the advice and opinion of a conformity assessor (CA). A conformity assessor is a person or body of persons whose expertise is or includes the carrying out of procedures (including inspections, tests and certifications) for determining whether the design and specifications, the proposed installation method or programme or the proposed modification method or programme relating to a major amusement ride or the major modification thereof conform to any technical standard or requirement. A conformity assessor could be incorporated or not, and could be local or foreign.

Besides technical support, the conformity assessor will complement the qualified person with expertise in non-technical but critical aspects of ride safety such as ride management (e.g. layout of queue areas) and crowd control (e.g. access routes and barriers).”

https://www.bca.gov.sg/AmusementRideSafety/arsa_rides.html

No rough guideline was provided by the website. But according to UK’s guidelines, any inflatable set up outdoors on hard standing must have 165kg of pressure on each anchor point. An option to that is the drill and bolt system.

UK website, http://www.hse.gov.uk/entertainment/fairgrounds/inflatables.htm. states this:

- If you are buying an inflatable for work or renting one for an event, ensure it has been built to the current British Standard (BS EN 14960) and if it has, there will be a label on it saying so. If there is no label you may be taking a risk with the safety of those using it.

- The label will tell you when it was made, how many people can use it and what heights they should be.

- Every inflatable should have at least 6 anchor points, though bigger ones will need more. The operator manual that should be supplied with the inflatable will tell you how many there should be. BS EN 14960 also provides more information regarding the calculations to be used to work out anchor point requirements.

- All the anchor points must be used, preferably with metal ground stakes at least 380mm length and 16mm diameter with a rounded top. Anchor points on the inflatable should have a welded metal ‘0’ or ‘D’ ring fitted to the end. If ground stakes cannot be used then a system of ballast using water or sand barrels or tying down to vehicles that will give at least the same level of protection should be used. Each anchor point should have the equivalent of 163kgs to give this. Beware of tripping hazards if you secure in this way.

- Have a good look at the inflatable when it is blown up and before use. You should check:

- the site is suitable;

- all anchorages are secure and in place;

- ancillary equipment is in position (e.g. impact-absorbing mats);

- there are no significant holes or rips in the fabric or seams;

- the correct blower is being used;

- the internal air pressure is sufficient to give a firm and reliable footing;

- there are no exposed electrical parts and no wear on cables;

- plugs, sockets, switches, etc. are not damaged;

- the connection tube and blower are firmly attached to each other;

- the outer edges of the front step are in line with the centre of each of the front uprights. Under no circumstances should the width of the step be less than this. The whole unit should look symmetrical and those bits that should upright, should be upright. If it looks misshapen or deformed there may be internal problems which may make bouncing unpredictable.

- If there is an electrical blower with the inflatable this must also be tested at regular intervals. The law requires electrical equipment to be maintained to prevent danger. The type and frequency of user checks, inspections and testing needed will depend on the equipment, the environment in which it is used and the results of previous checks.

British Standard (BS EN 14960) costs 114 pounds to buy, and it will be unnecessarily time-unfriendly. I will adhere to what I can find on the above UK website.

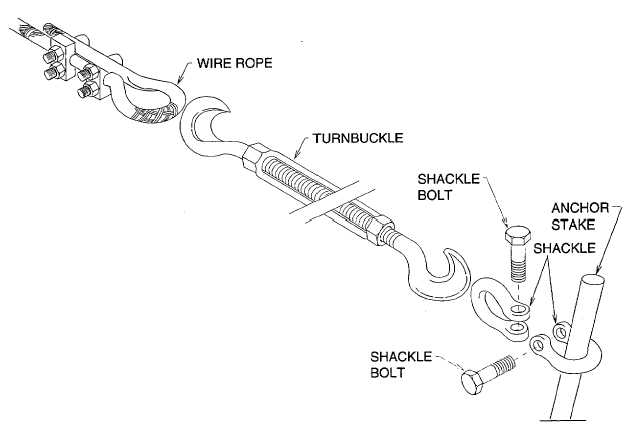

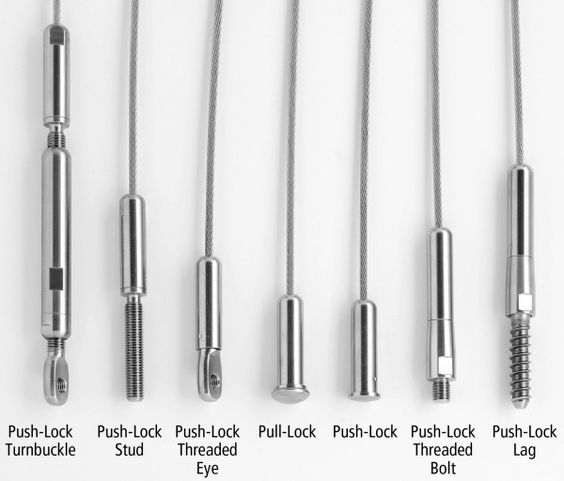

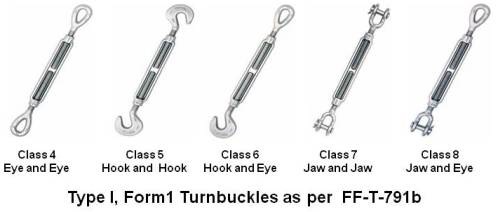

Turnbuckles

The floor panel holding the shackles must be able to withstand harsh outdoor environments.

HDPE Marine Board

High Density Polyethylene Marine Board is specially formulated to withstand the rigors of harsh outdoor marine environments. It is UV-stabilized to resist damage and retain its beauty, even after years of direct sunlight. Increasingly, Marine Board is replacing wood and laminates in boating applications. It does not splinter, crack, delaminate, rot, swell or absorb water like traditional materials. Even under heavy foot traffic on yacht decks, it remains virtually maintenance-free.