SILK SCREENING

It was my very first time at silk-screening on the previous week and I had trouble conceptualizing the process because I simply couldn’t fathom how our printed designs on TRANSPARENT PLASTIC (Correct term: Transparency Paper) could be translated onto printed designs on tote bag while using this sieve looking tool (Correct term: Silk Screening frame).

I had to see and have hands-on experience to believe this amazing invention created by mankind!

Firstly we were told to wash our silk screen frames and use a hair dryer to blow dry them, to ensure they were clean!

Then we went into this enclosed red room ( Red light was present) where NO LIGHT was allowed to be present as there might be some chemical reaction with the medium we were going to use. We then coated the netting of our frames on the back and front using the blue paint-like medium and then placing our coated frames in this GIAGANTIC oven (It had really smooth rolling trays…) to dry the medium !

After which we were taught by Xiuming (Work-study senior) to place our transparency and frame into this GIGANTIC MACHINE which looked like a photocopy machine on the outside, but had like reflective metal on the inside which made it look like a tanning machine. After which we locked our designs in the machine, it made a whirring sound and the cloth above our designs was like sucked in!!! I was super amused at this point because I had never seen anything like this before!

The Photocopy looking machine which printed our designs onto the silk screen frame surface 🙂

After which the machine did it’s job, we took our designs to the back of the room to wash the residue off using this jet spray (It was fun… pretending that the jet spray was a rifle  )! But in all honesty, I was rather upset at the amount of water wasted in this process of washing… considering that all of the students in ADM Year 1 had to do this, it is bad for the environment by wasting so much water. :'(

)! But in all honesty, I was rather upset at the amount of water wasted in this process of washing… considering that all of the students in ADM Year 1 had to do this, it is bad for the environment by wasting so much water. :'(

This jet spray allows the residue to be forced out of the net!

After cleaning up our designs on the frames, we used the hairdryer to dry the frame and apply a layer of thick ink over the top of our frame and pushed the ink across the designs using a wiper tool to ‘print’ our designs onto our tote bag!

Drying the design

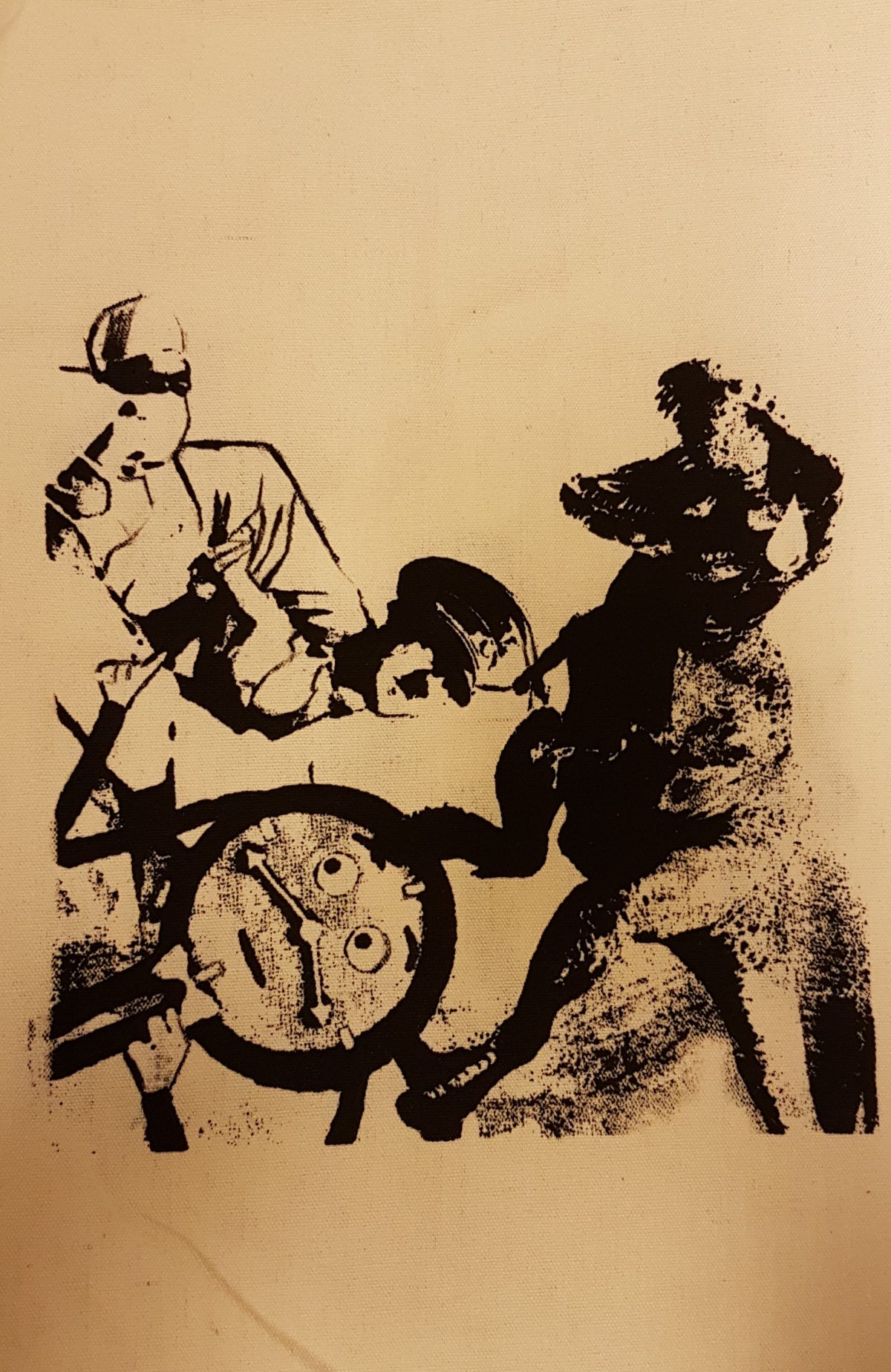

I wasn’t very please with the eventual outcome on the tote bag as some areas were too dark and splotchy instead of greyish, and details were missed out… As you can see it is pretty in-identical to my digital design.

After test runs on paper, the final design has been printed on my tote bag!

<<<Original digital design after bitmap

<<<Original digital design after bitmap

What I regretted the most after the final printing onto my tote bag was not being able to have a good gauge of what my final print will look like based on the tonal contrast, quality of the digital image and frequency of the dots in bitmap, BEFORE printing on the transparency paper … I hope that in the future I can have more opportunity to try out silk screening again. It was really fun! But at the same time, the process of silk screening was not easy at all; and I really do commend those who could do it so well!

If my personal experience with silk screening is not detailed enough, do check out this video on how silk screening is conducted!!

Cheers!

Seng Yi Ling