Creating Unconventional Fabric using Threads, plastic

– Plastic Fusing

– Fabric of Thread

Plastic Fusing

Plastic Fusing is the creation of plastic made fabric by heating and melting the plastic letting them stick together to create a large piece of fabric where it could be later use to create various products, costume, outfits, stationary etc.

Materials Used:

– Iron

– Scissors

– Plastic Bags

– Baking Paper

Experiment 1:

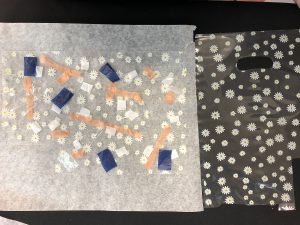

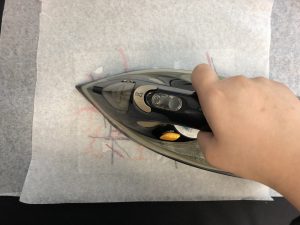

Start by cutting and placing the plastic to create the design you want. After, place the design on you iron board with the baking paper on the bottom followed by your design and lastly another layer of baking paper.

Heat it with iron and press it with pressure. Do peel up the baking paper halfway to check if the plastic are melted consistently. Be careful when doing this because sometimes the plastic may stick onto the top baking paper when you try to peel it up.

FINISH!:)

Experiment 2:

I tried to cut the plastic onto strip this time round also also instead of plastic on the floral plastic. I tried by placing the strip plastic onto bubble wrap.

Heat it up and remember to check:)

FINISH!!

Fabric of Thread

Fabric of thread is the creation of fabric using the combination and joining of thread using water soluble stabilizer. It could then be use to create outfit or other products such as lamp shape or even bowl etc.

Materials Used:

– Sewing Machine

– Water soluble stabilizer

– Thread, Yarns, Fabric Strips, Trimmings

– UV resistant clear acrylic spray (for securing of shape)

Demonstration:

Experiment

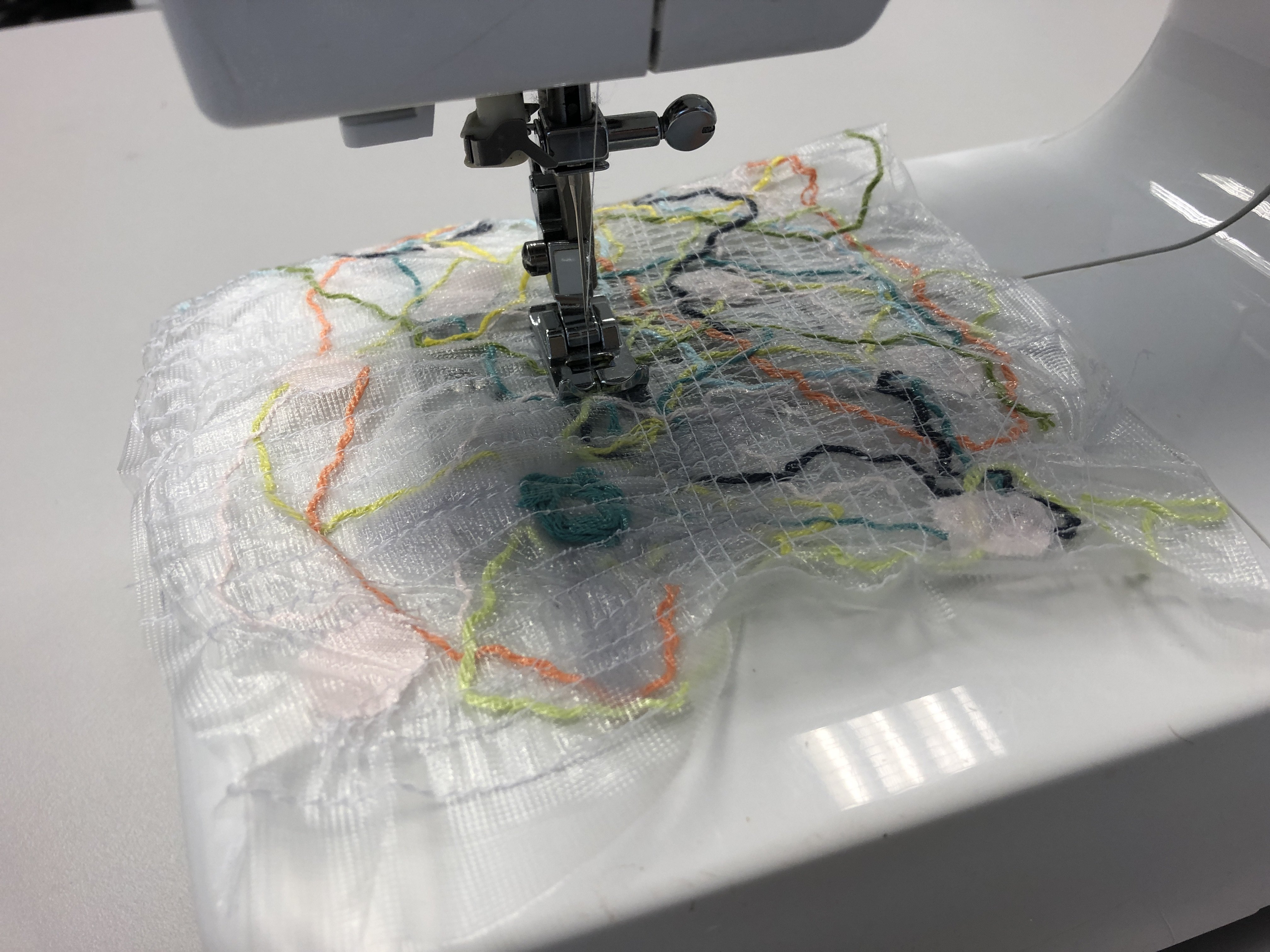

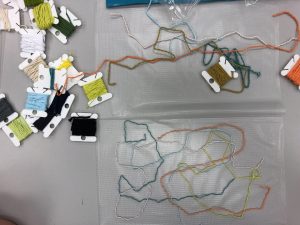

Cut and create your design by placing the thread onto Water soluble stabilizer. Do remember to put it in between the Water soluble stabilizer.

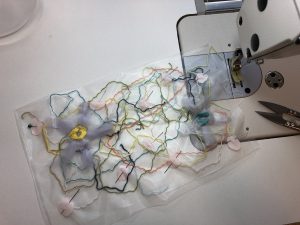

Secure your threads and items on Water soluble stabilizer with fabric pins. After sew them with a sewing machine, the simplest way to secure the thread in position are going in a up down method with sewing with sewing machine.

I decided to challenge myself with the industrial sewing machine as we don’t get much chance to try it. But it was way to hard to control the speed of the sewing machine. Maybe I just have stupid legs hahahaha. Anyway, I transfer to the normal sewing machine to speed up and also to try both machine hehe:)

Front and Back.

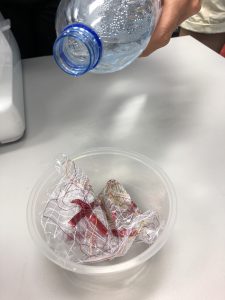

Prepare the needed material to dissolve the Water soluble stabilizer. You’ll need water, Moulds (optional), Your Work and an empty container.

Put your work into the empty container and pour water in. Slowly rub on the Water soluble stabilizer and it would dissolve:O

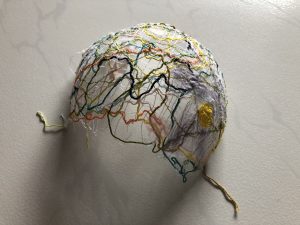

After that you could put it on a mold and let it dry of simple leave it flat. You could put onto anything as long it is strong enough to help you hold onto your desire shape:)

TADA!!

Reflection:

It was really an interesting technique and something that I have never tried before, It is challenging using the sewing machine especially controlling the speed of it. However, once you’re done and once you wash and dissolve it the remaining pattern are really beautiful. If I have a chance, I would like to try and create something more 3D probably a shape I design or even sewing them together to create the shape after I have dissolve them:)