Thermoplastics

Thermoplastics are fabrics that can be manipulated and shaped using heat and pleating, crushing or moulding techniques. When heated, the polyester organza will soften and take the shape of the mould or object and will retain this shape when it cools. The organza can be reshaped when heated once more to an even higher temperature.

Materials needed

- 100% polyester organza (no nylon!)

- Objects to mould the organza with e.g. marbles, stones, glass beads etc

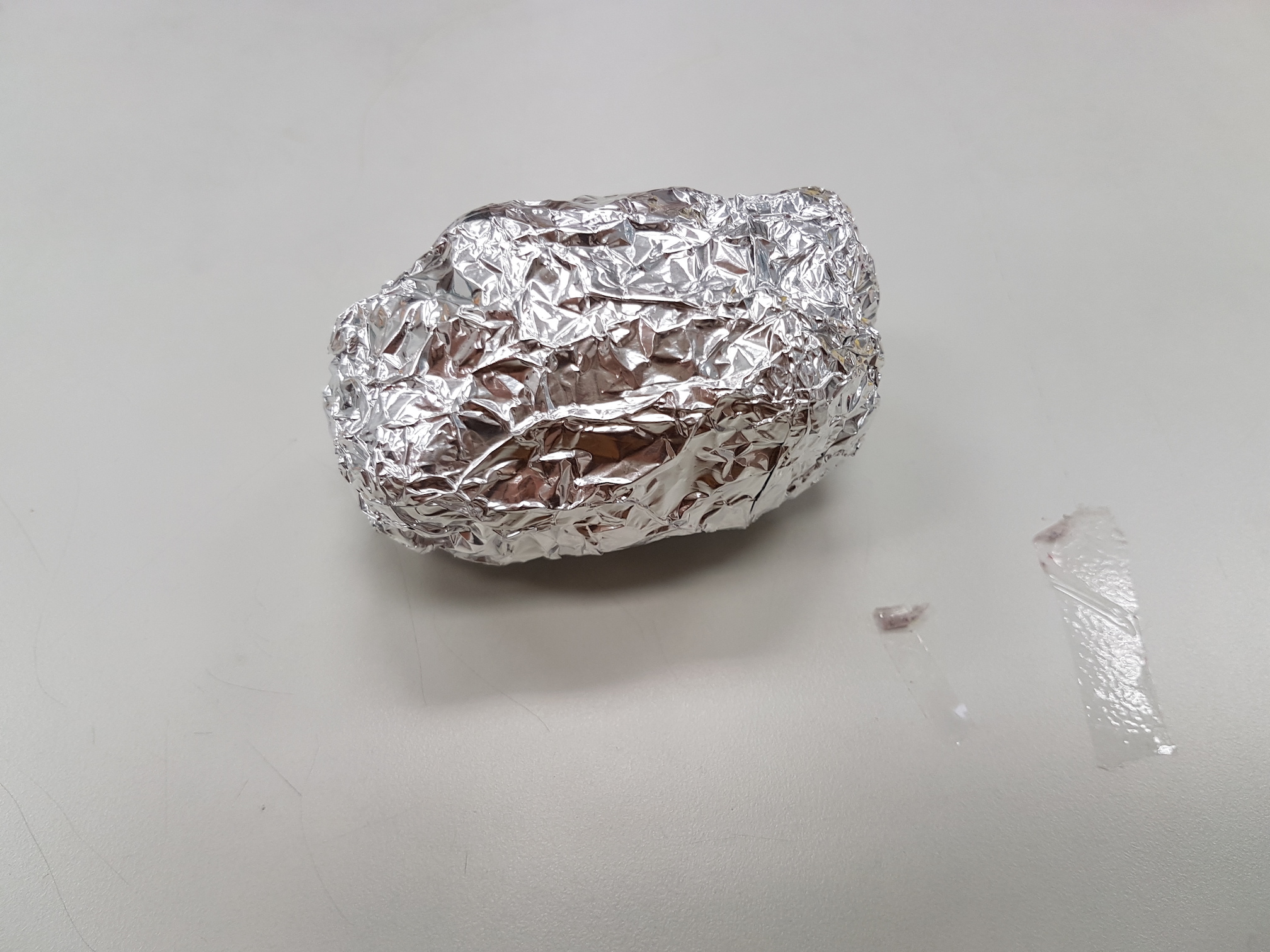

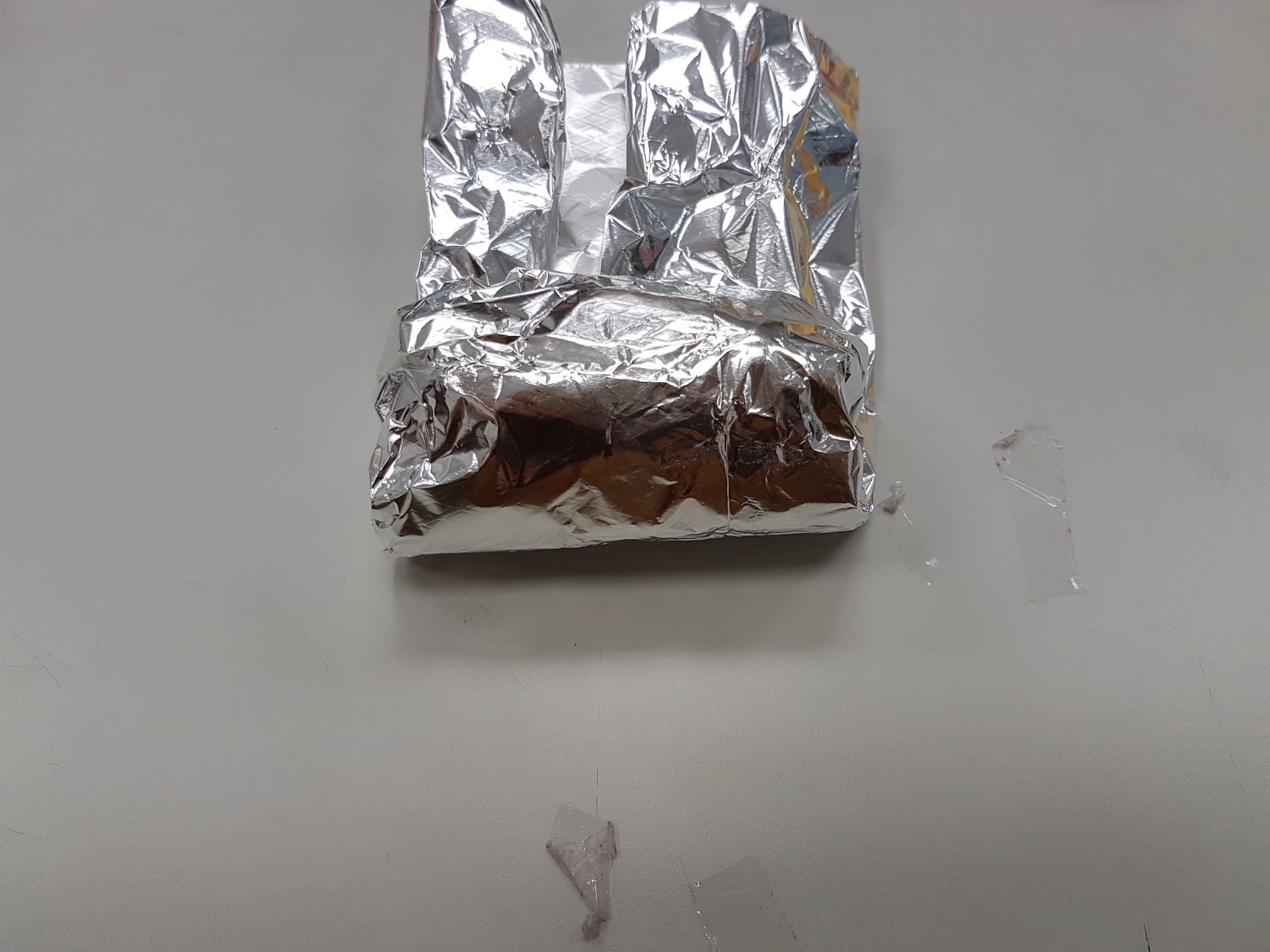

- Aluminium foil to pleat the organza and wrap the sample

- Large pot of water and stove

Applications

Heat set thermoplastics are sometimes used in decorative cushions or lamp shades due to their semi-transparent nature.

Here are some interesting samples which we saw in class:

Process

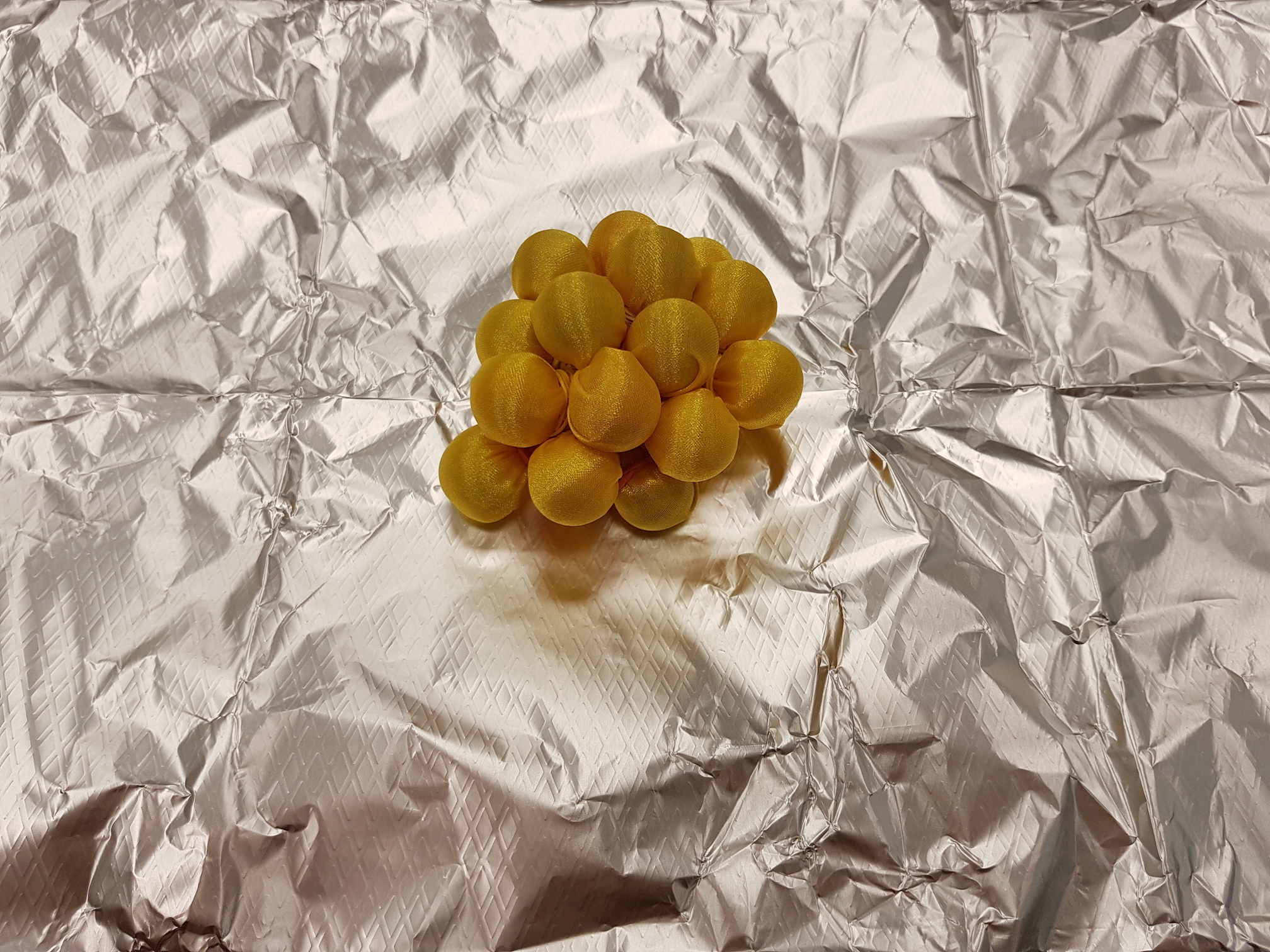

Mould, fold or manipulate the polyester organza using objects (e.g. marbles, stones) and secure with elastic bands. Alternatively, pleat and fold the polyester organza between sheets of plastic, paper or aluminium foil. Fold the organza into multiple layers to get a repeated pattern over a larger area of fabric. The sample below is folded into 4 layers.

Wrap up the object in aluminium foil before boiling and steaming in hot water.

Unwrap the foil and let the organza cool down in the desired shape. Do not hang the fabric or remove the rubber bands or marbles when still warm, as this will loosen its shape.

Remove the rubber bands and mould objects when dry.

For my final project, I imitated the shape of the pine cone petal using thermoplastics. I wrapped organza around different sizes of disposable spoons to simulate the different petal sizes.

This technique of manipulating thermoplastics with heat is very interesting and enjoyable! It allows us to create organic shapes and mould a soft fabric into a rigid semi-translucent form. There are endless possibilities!

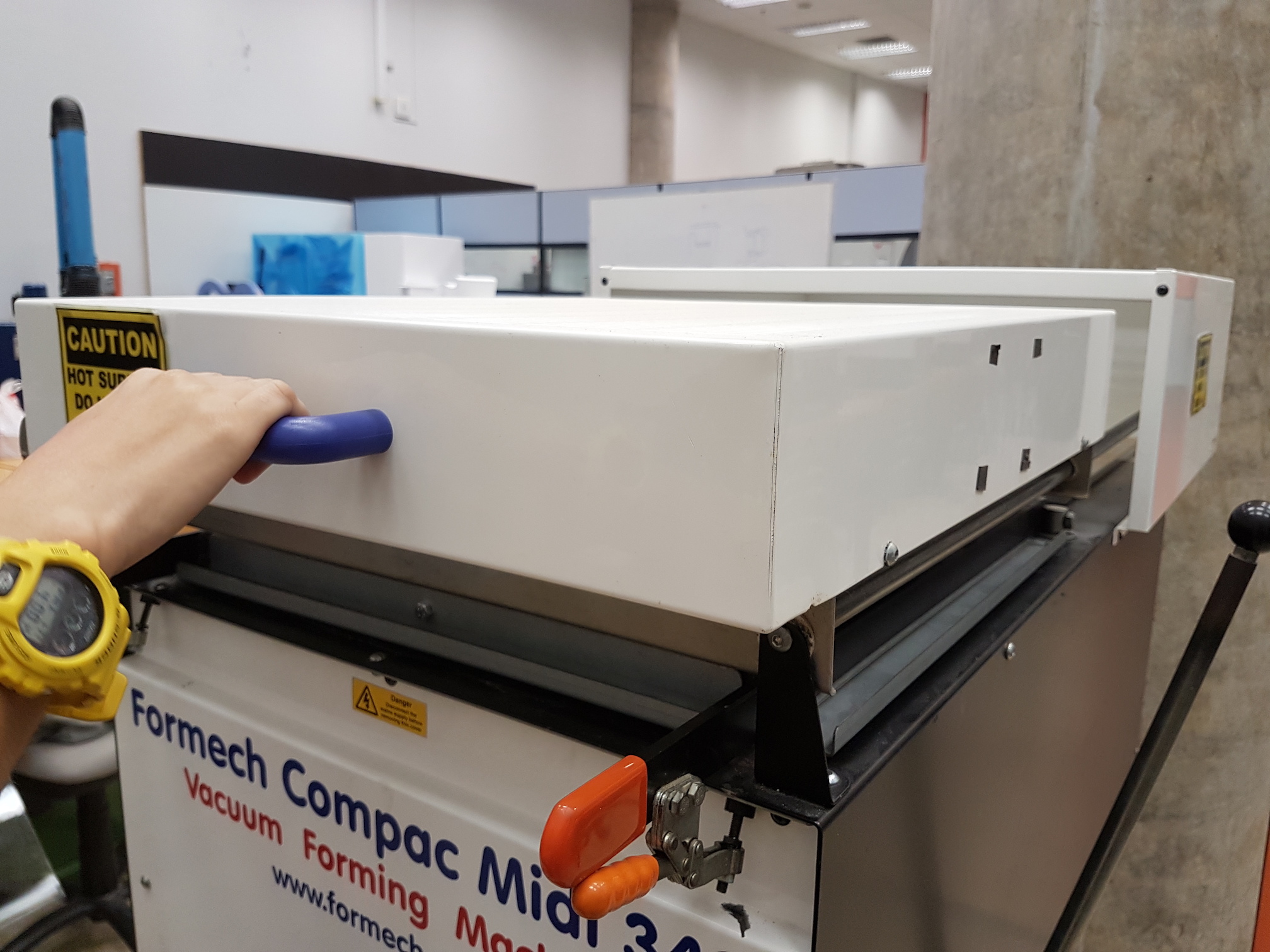

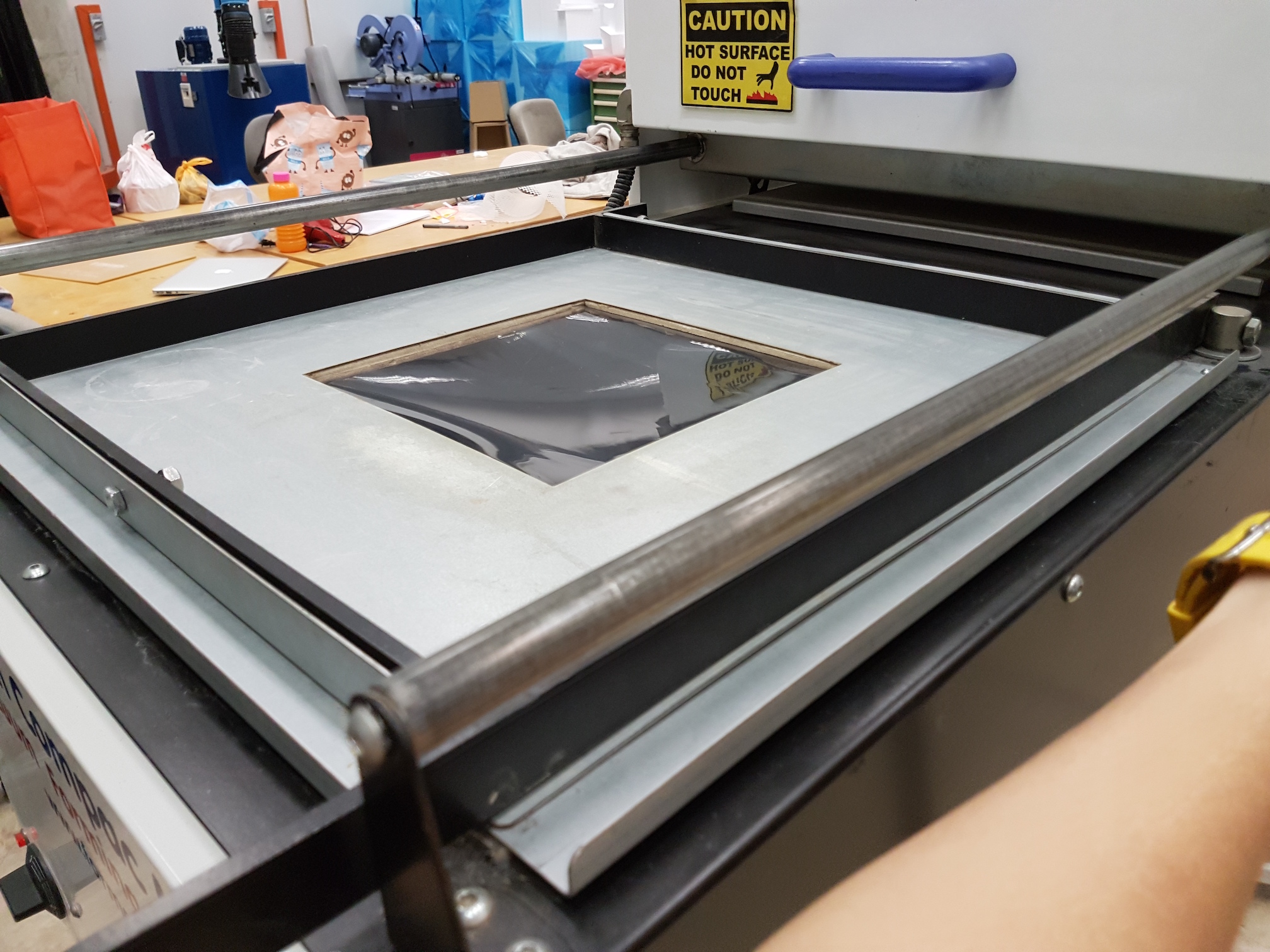

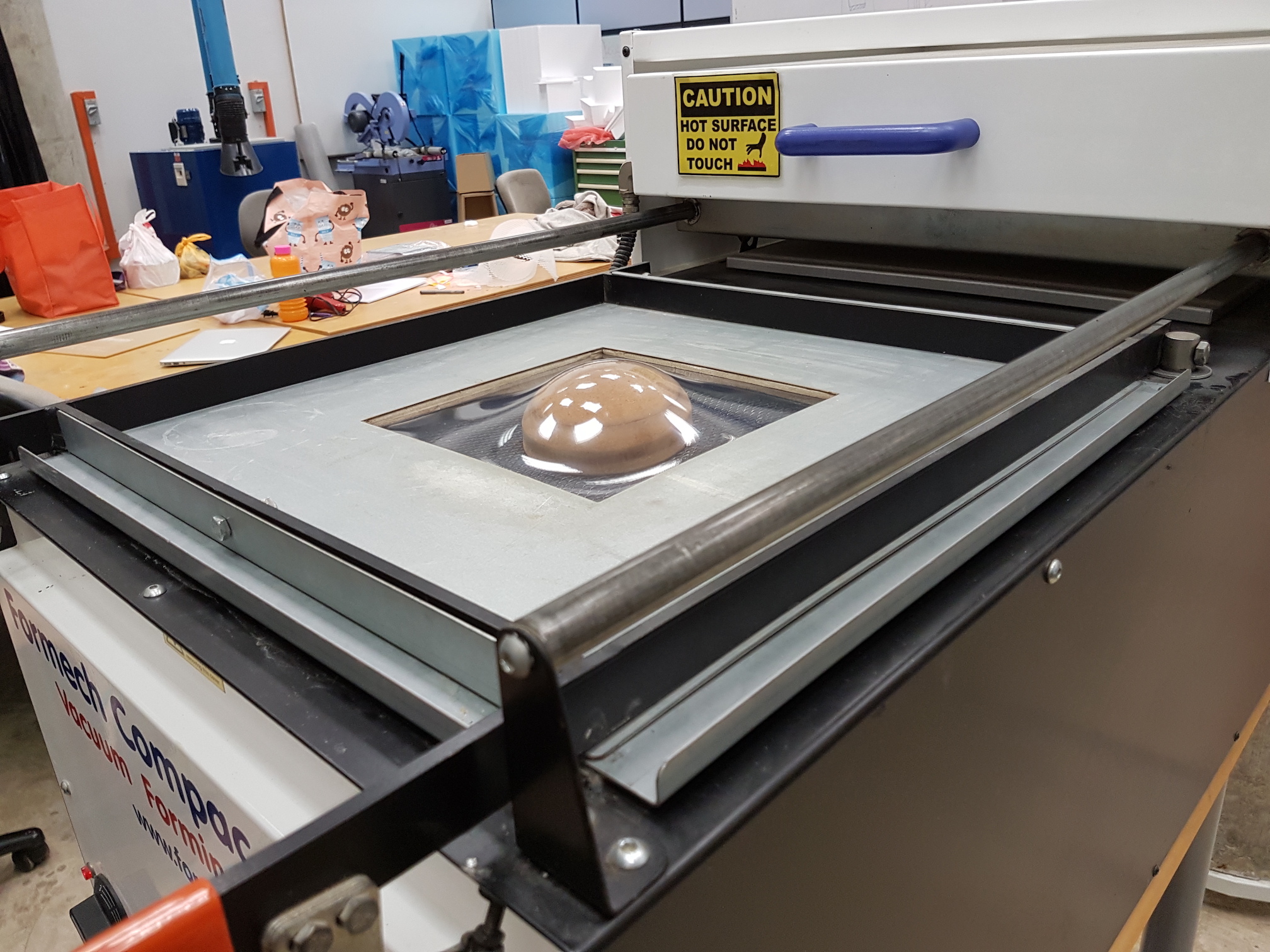

Vacuum-forming

Materials needed

- Vacuum-forming machine

- PVC plastic sheet

- Objects to form around

Process

Cut out an appropriate size of PVC sheet. The vacuum forming machine has 2 default sizes. Use objects with a concave shape so that they can be removed after forming such as domes (Spheres can’t be removed!). Vacuum forming can be used to create moulds for other materials such as latex and resin.