Unconventional materials: Plastic fusing and threads exploration with soluble materials

1) Plastic Fusing:

Materials:

1) plastic bags

2) Food wraps

3) Food Nets

4) Fruit wrap foams

5) Threads and Yarns

Technique:

1) Place a piece of baking paper underneath

2) Layer and design all the materials that are chosen on the baking paper

3) Place another layer of baking paper on top of your design and iron over.

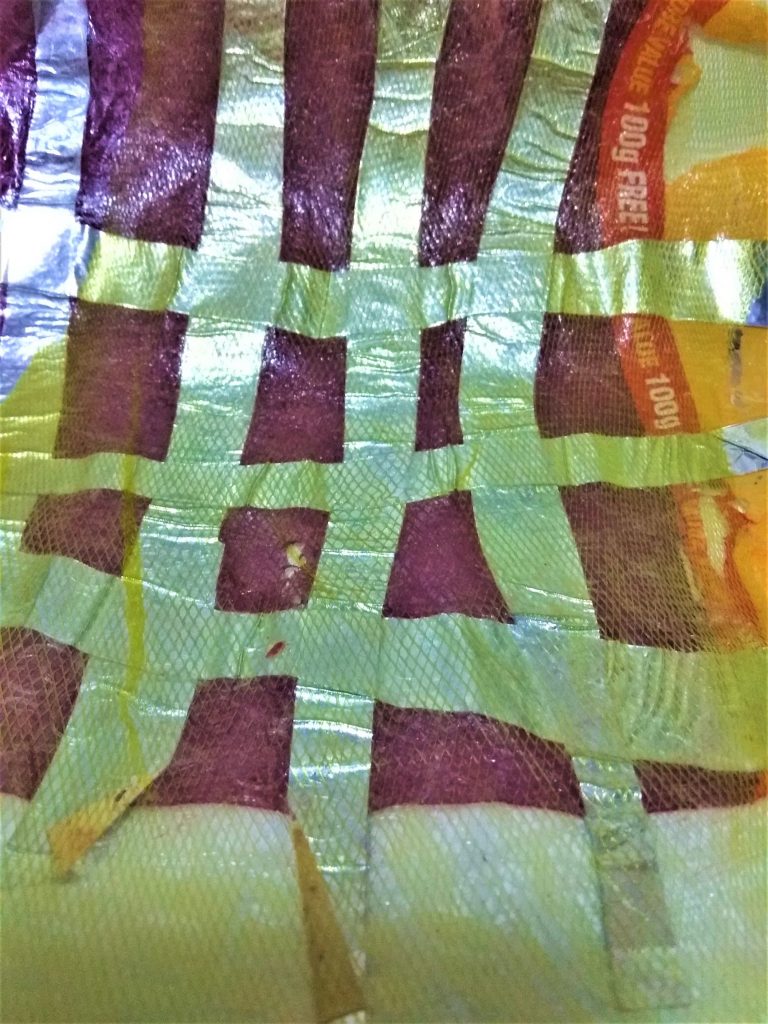

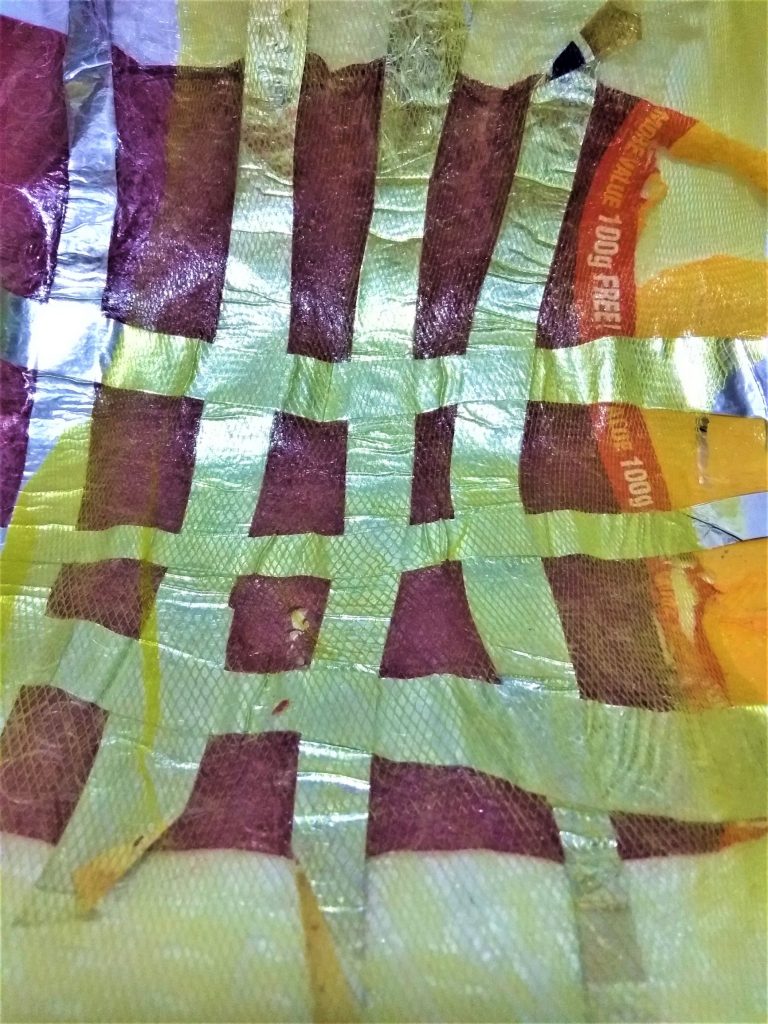

Trial #1)

In the trials for plastic fusing, I would like to explore both unconventional materials from different types of plastics as well as having a green concept. Most of the plastics I have gotten are recycled food wraps from potato chips, bread loaves, garlic, and onion nets, fruit foam nets, etc. Considering that all of these are different types (thickness and quality) of plastics, I am curious as to how they will fuse together under heat from the iron.

Maroon wrap – Bread loaf

Sliver strips – potato chips

Yellow net- garlic holder

Bubble wrap

The bread wrap was the first to have the effects of fusing as it was rather thin. The silver strips were harder to fuse as they were slightly thicker. The yellow net actually shrunk in size visibly to a large extent as the heat was applied causing the layers below to curl and crunch together. The bubble wrap became so thin and because of its transparency, the effect became negligible.

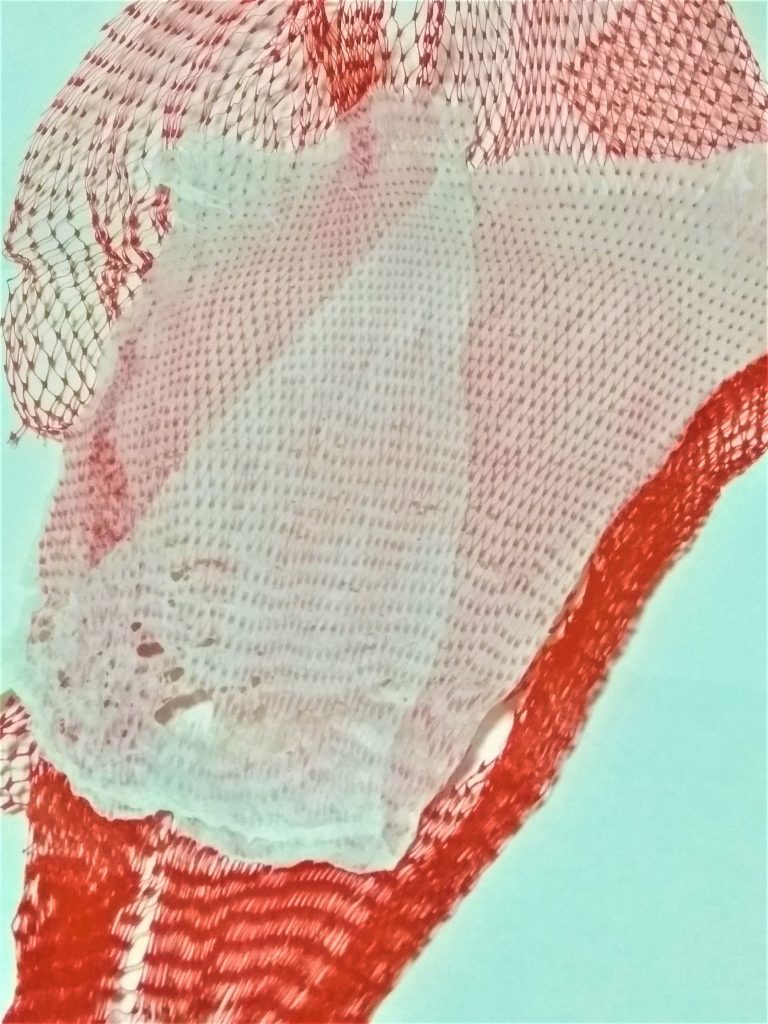

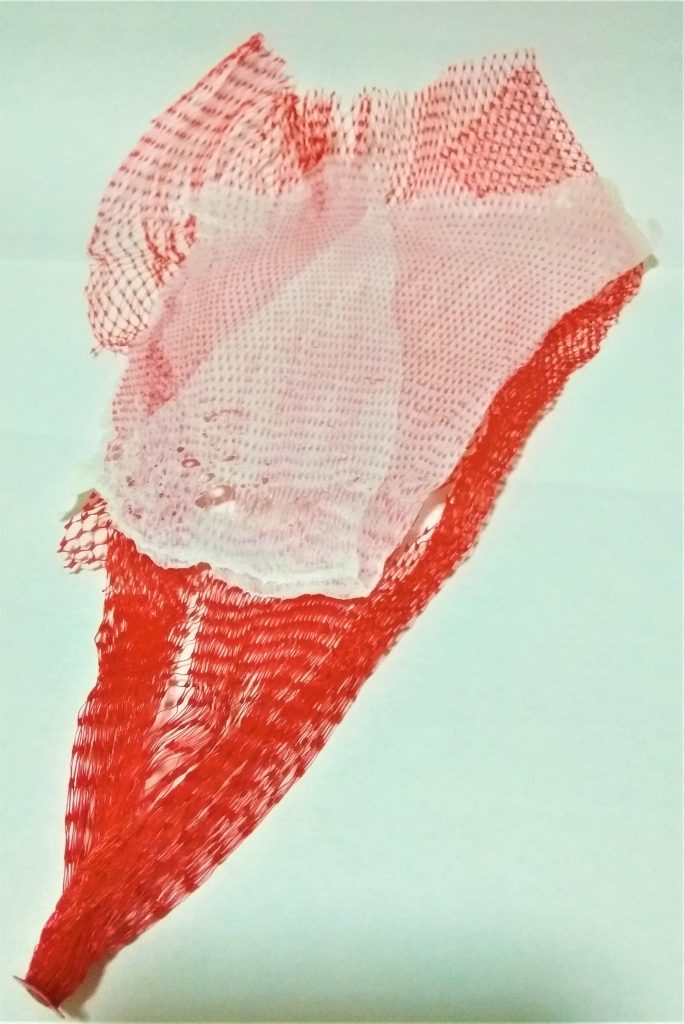

Trial #2

Materials:

- Coarser plastic nets from Onions holders

- A white plastic bag from grocery shopping

This took an incredibly long time to fuse even though the simple white plastic bag melted quickly. The red netting shrunk in size visibly and due to the shrinking, it has caused the white plastic as well as some netting to crunch up and overlapped. On parts where the netting and white plastic fused together nicely, the effect that I had gotten was a rather nice and thick piece of fusion. However, surrounding the middle area, there is an uneven thickness of fusion especially when the red net overlapped with one another.

Trial #3

Materials:

- Fruit Foam Wrap

- Yarn Bits

- Bread Loaf Wrap

- Cereal Food Wrapping

For the third trial, I placed bits of yarn on top of cereal food wrapping and a thin layer of the white plastic bag on top. However, the thin layer of plastic bag fused into the yarn threads quickly and the effect was not as apparent, it also did not look like the yarn bits were attached very well onto the cereal wrap. In order to create a plastic fusion sandwich, I added a piece of maroon bread plastic wrap on top and it created a nice fusion with spongy feels. The fruit foam wraps, on the other hand, melted into a thin piece of plastic that has a negligible effect on the fusion.

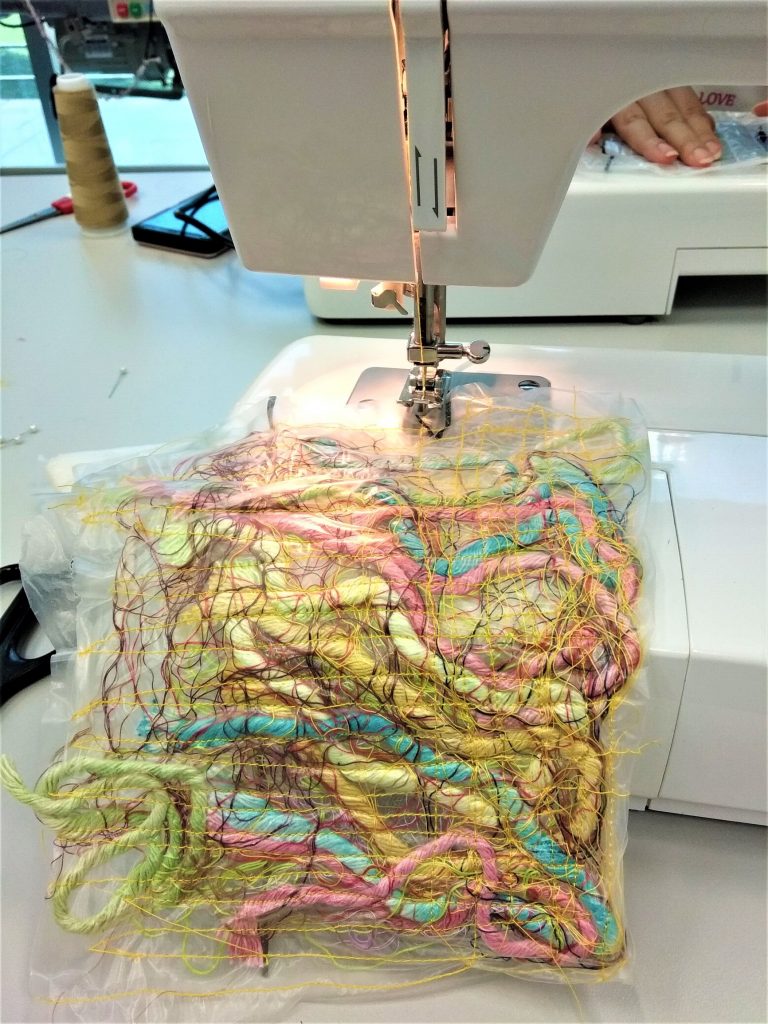

2) Threads with soluble material:

Materials:

Yarns and threads, sewing machine.

Steps:

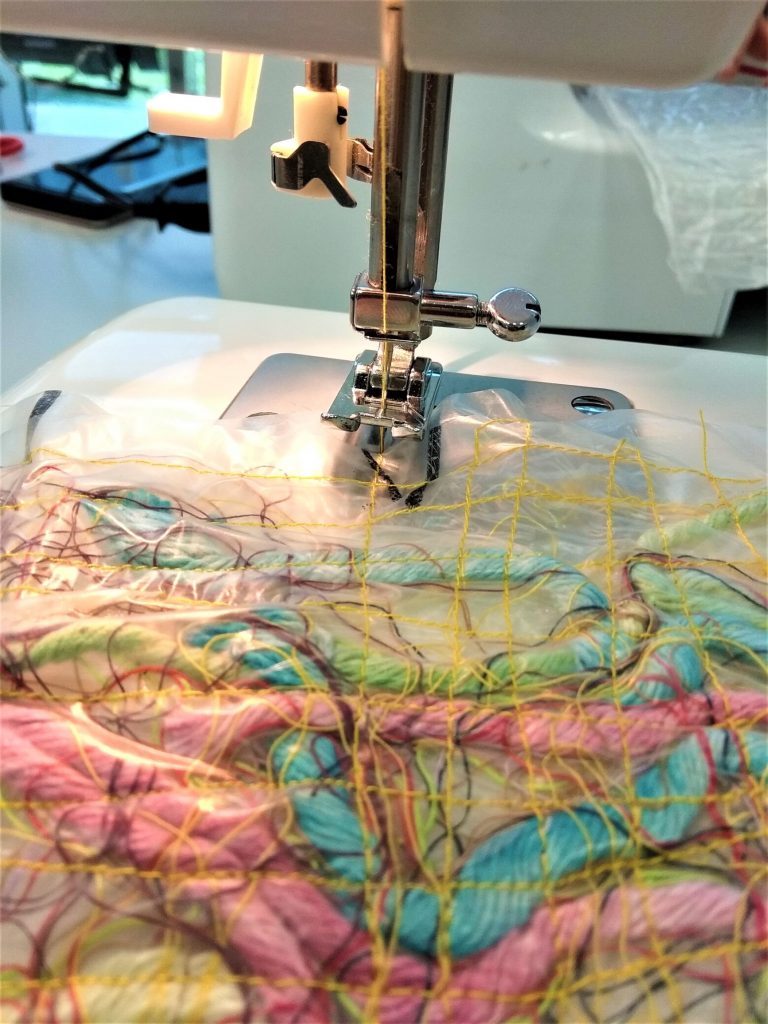

- On a layer of water-soluble sheet, place all desired objects on top of it.

- Fold the layer of soluble sheet into 2, covering all the yarns and threads.

- Pin all the objects down

- Sew along the 4 edges to create a border first before sewing in a grid manner.

- Remove the pins that holds the threads and yarn in place as you sew.

- After sewing, wet the piece and place it over a bowl or cup to keep the form in shape and leave to dry.

Trial:

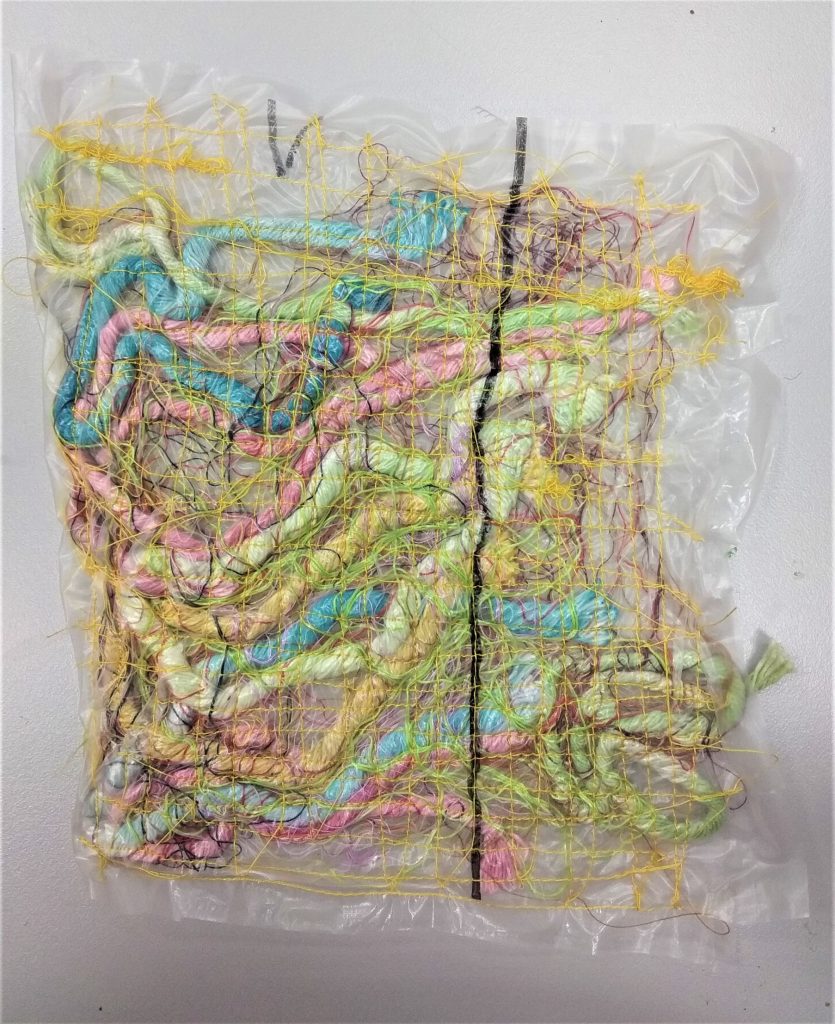

Outcome:

I pressed the woven soluble piece over a rounded overturned plastic container and dissolved the soluble sheet gradually while adjusting the shape of the piece. The process was very gooey and sticky. I felt that the water-soluble material seems to be made from starch, something that is non-toxic and highly soluble. I left it to dry for 1.5 days and this is the result.

Overall, it formed a nice shape and did hardened enough to keep the shape by itself without the plastic container mold. As compared to the plastic fusing technique, this water-soluble technique is slightly more interesting in the sense that it is easier for the fabric to evolve into something more abstract using the patterns/designs/placements of the various threads, yarns and colours used. It is also highly moldable and takes shape after the type of container or cup used to dissolve the water-soluble material. On the other hand, the plastic fusion result is slightly more rigid compared to this. Hence, I do see more potential using the water-soluble technique to create something more diverse and vibrant.

Applications:

Garments made from plastics.

Garments made from recycled materials.

Water-soluble materials with threading techniques-seamless linearity (projected outcome)