For the final project for robotics, I decided that I want to do a solo project as to explore and learn more about the robotic aspect.

Categories that I am interested in:

Animatronics:

The use of Robotic Device to emulate human or animals, or to bring lifelike characteristic to inanimate object-

It integrates:

Anatomy

Robots

Mechatronics

Puppetry (research to be done: Karakuri Puppets)

Usually powered by:

Pneumatics

Hydralics

Electrical

Mechanical

And controlled by:

Computer

Human (teleoperation like remote)

And further research must be done on:

Structure – Frame/Skeleton(Material, Skin)

Components – Types of motors and usage

Automaton

They are self-operating machine or mechanism that automatically follow a predetermined sequences of operations, for me, they are more like the 3D – Dumb, Dull and Dangerous of robotics that does job that would reduce manpower.

The main aspect I think of Automaton is the ability of repeat-ability as they are supposed to do the same sequence over and over again so the zeroing of every cycle is of an importance here.

Areas to explore here:

3D

Healthcare

Unmanned Vehicles

Architecture

Medical

Entertainments

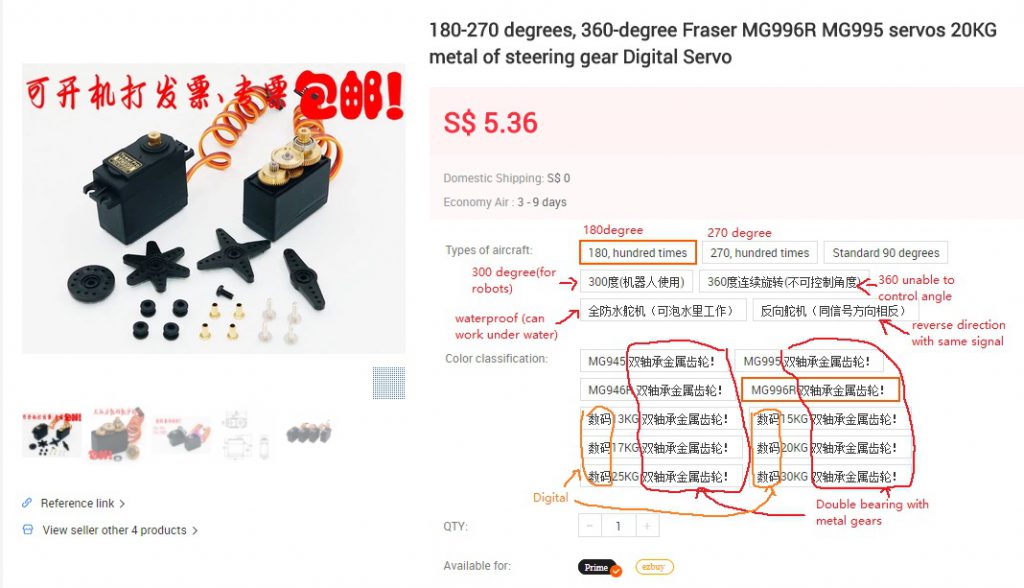

Stepper motor VS Servo Motor

Stepper Motor:

– Easier to control (1Pulse = 1 step)

– Higher Torque at low speed

– Relatively cheaper

– Accelerate too fast will result in skil step

– Higher vibration

Servo Motor:

– Generally High speed and High torque for given size

– Ability to maintain torque at high speed

– More efficient

– Does not vibrate much in comparison to Stepper Motor

– Generally more expensive

– Only limited types of servos

Overall:

Stepper motor is good for low acceleration and high torque applications and Servo motor is good for higher speed and higher torque applications.

My thoughts:

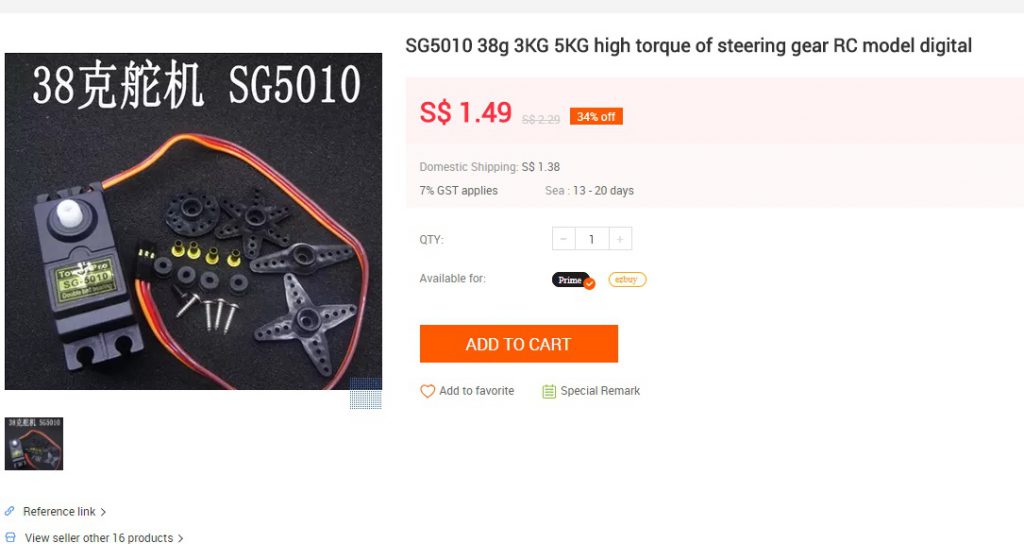

I could use 2 smaller servo to move a lever which is not capable by using only 1 servo instead of using a bigger servo (like 2x SG90D at 6V vs 1x HS322HD at 5V, but theres a limit to this)

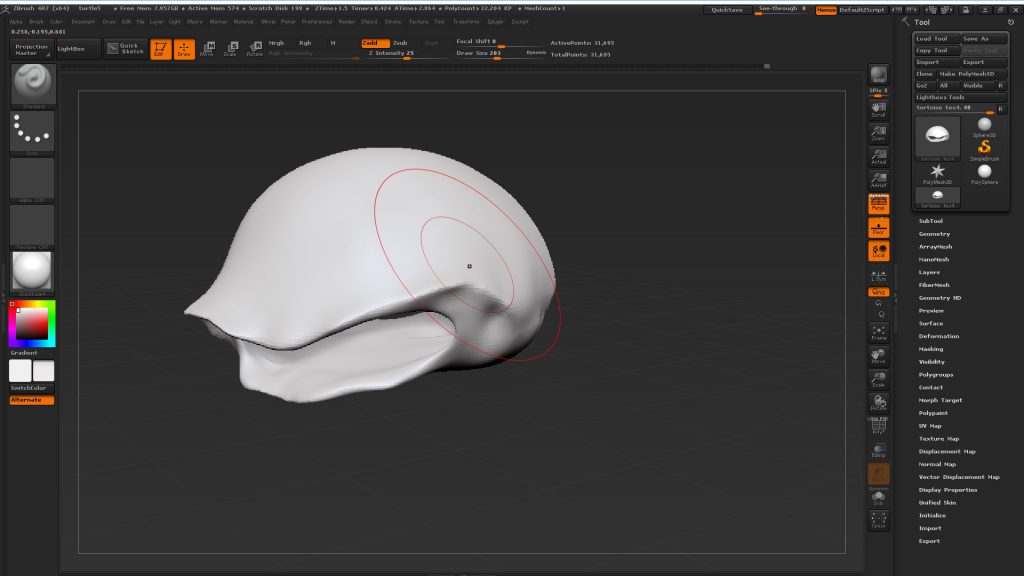

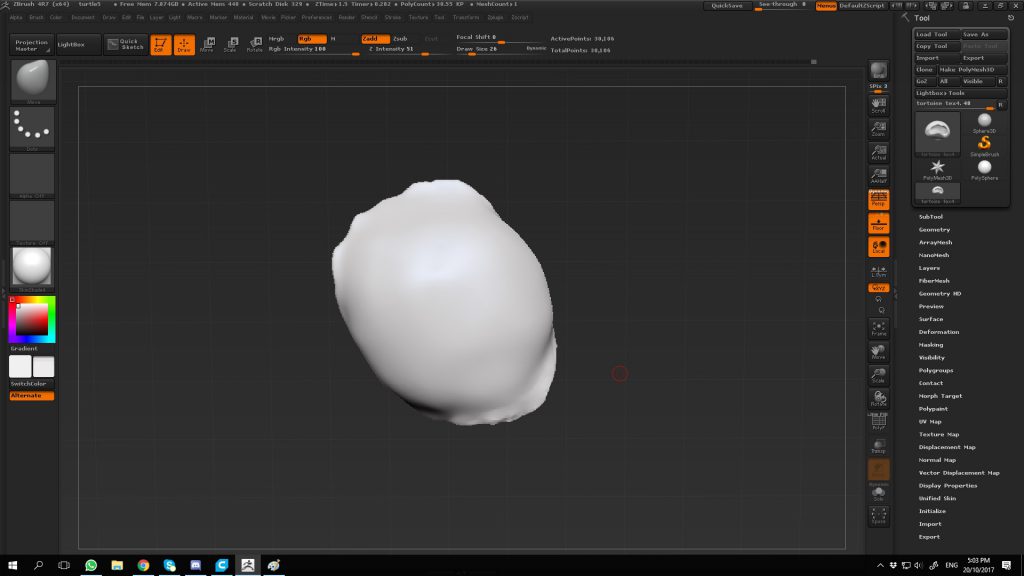

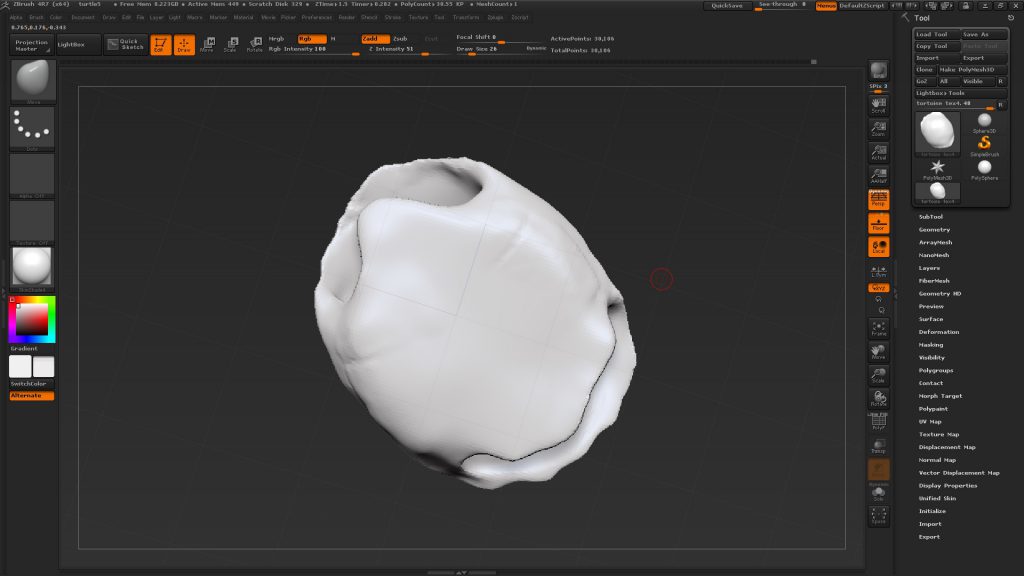

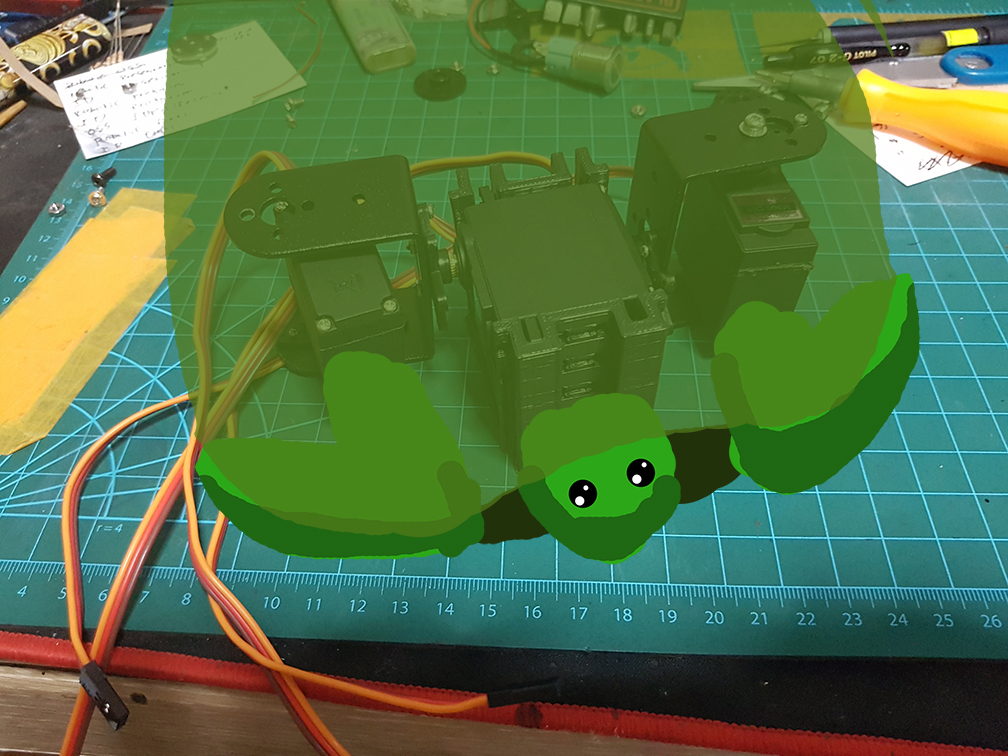

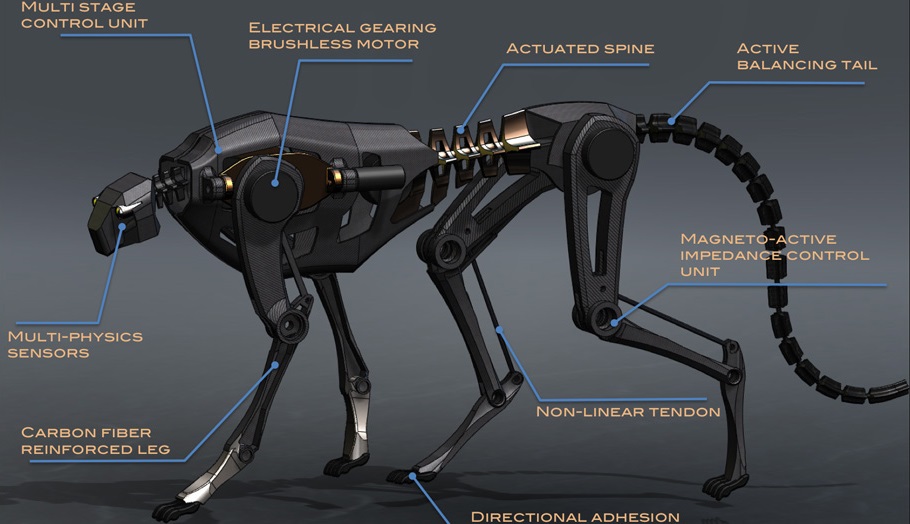

I am more inclined to Animatronics as it seems much more interesting for me, after some research about Animatronics, Hexapods and Octopods are really common among the field of robotics due to the stability (6/2 = 3, and 3 feet on the ground will be stable) but then I am really interested in Quadruped which has 4 feet and an quadruped animal which I really like was the turtle/tortoise as they are interesting, generally does not move too fast and naturally have a shell, which seems logical to use a turtle as a base as their nature suits what I am looking for and it will be easier to hide all the components. So for now, I really want to give a Robotic Turtle some thoughts.

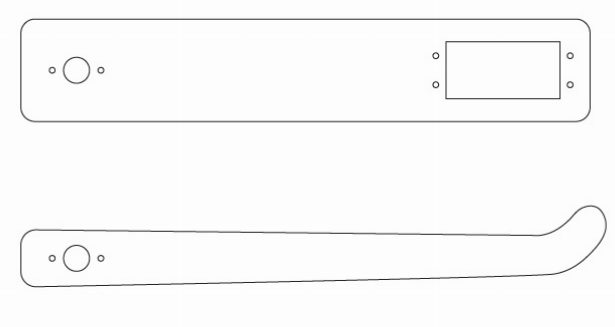

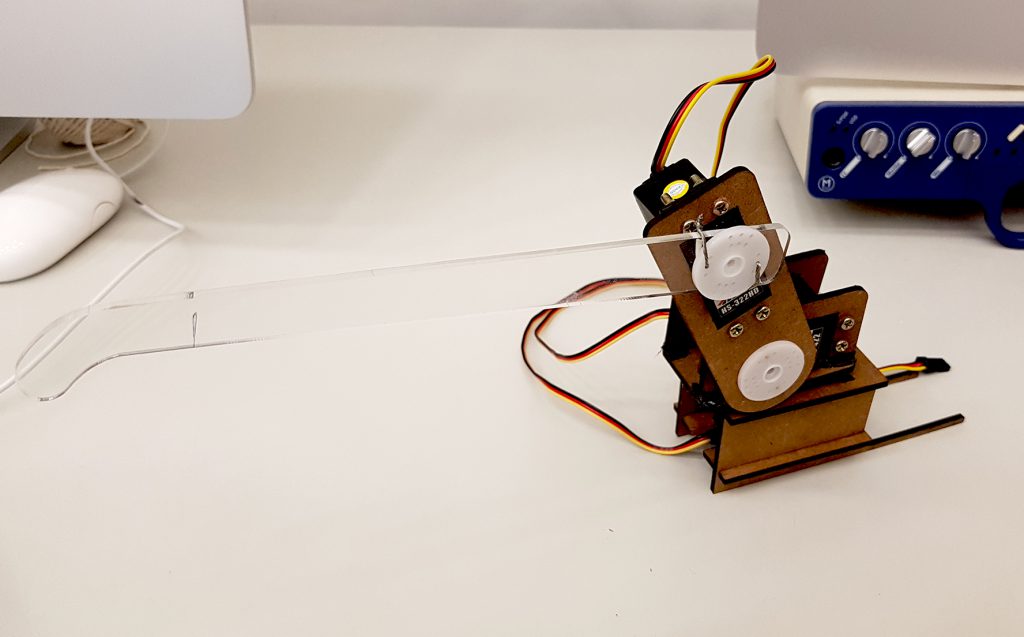

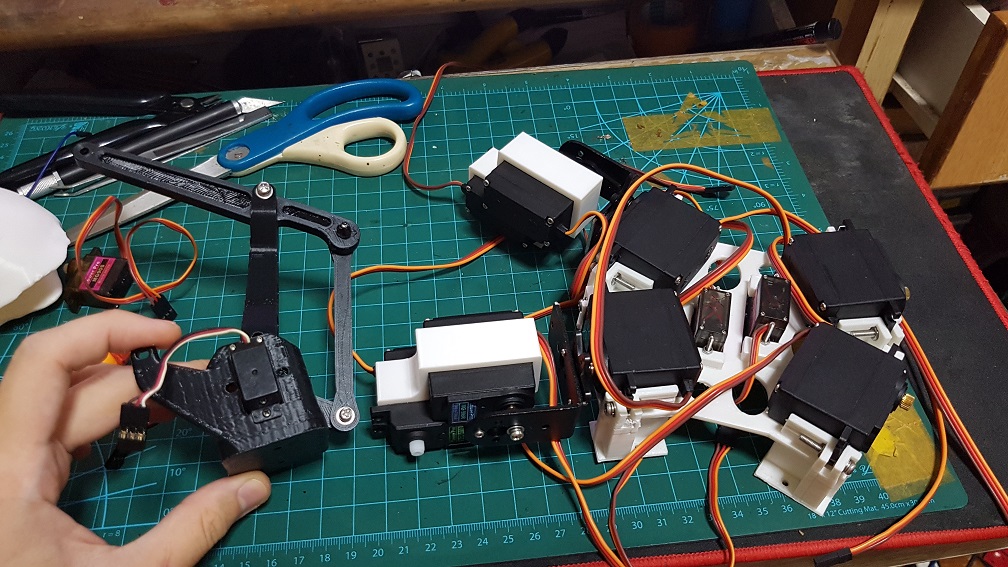

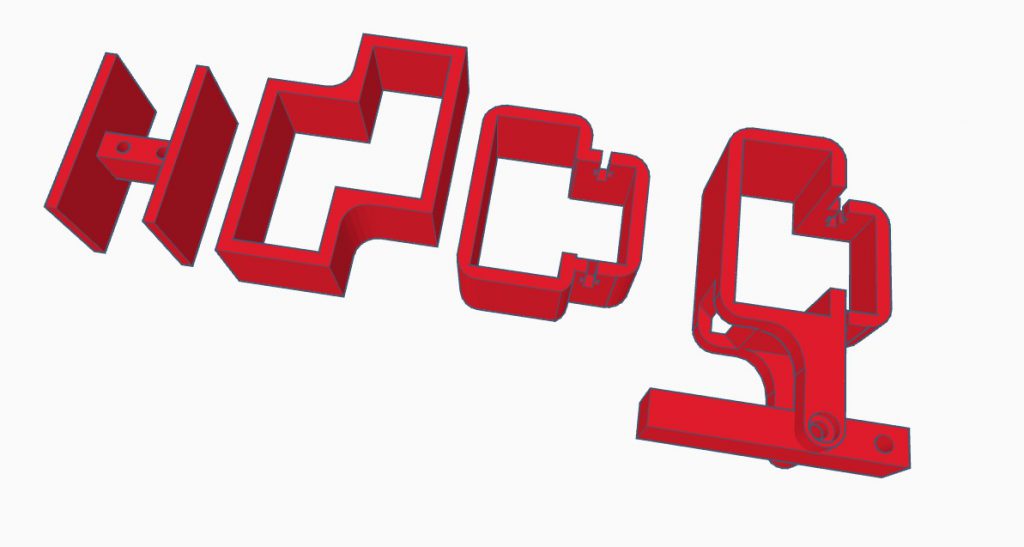

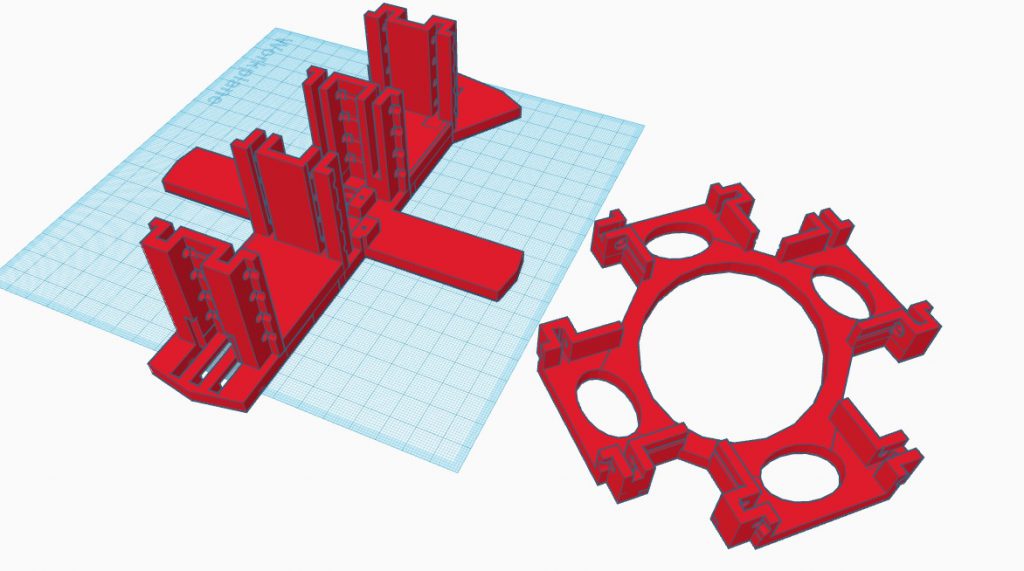

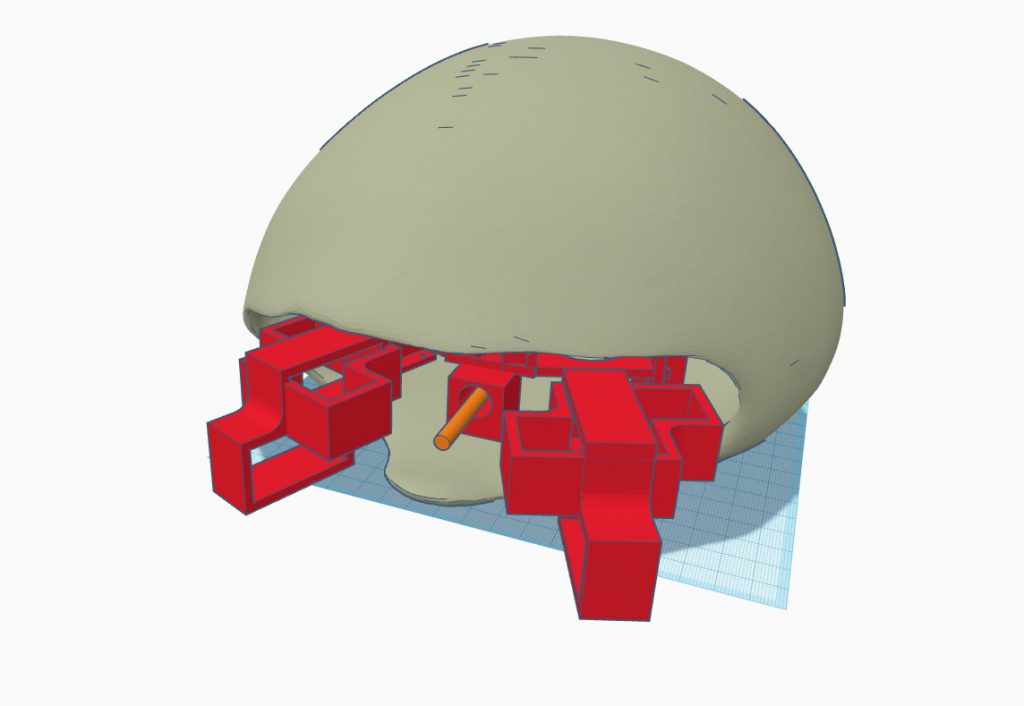

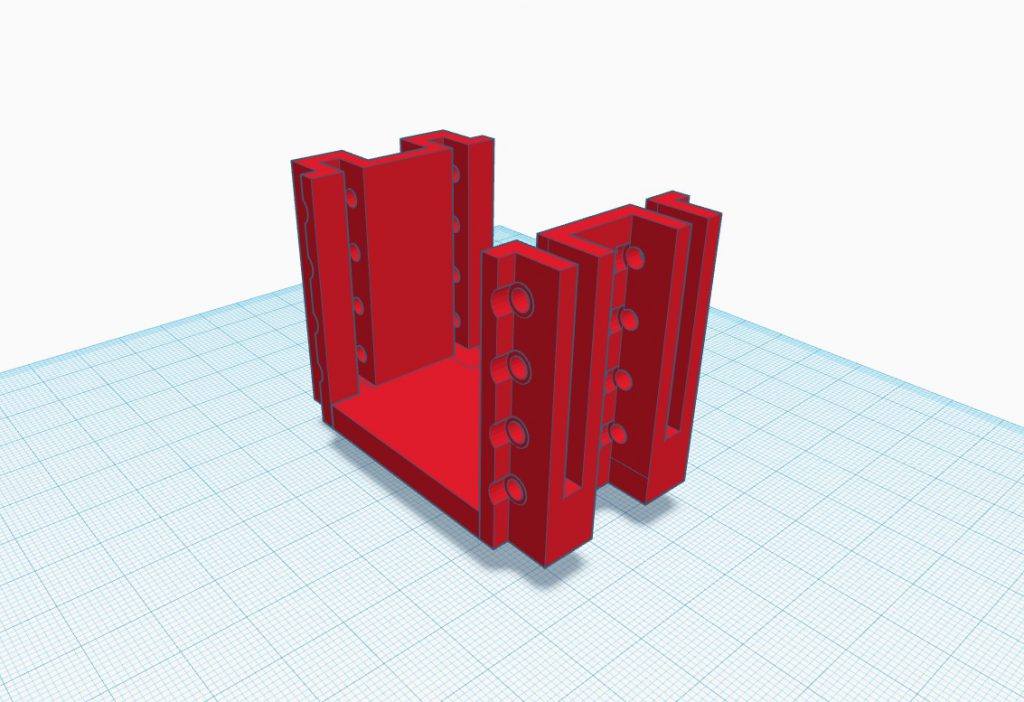

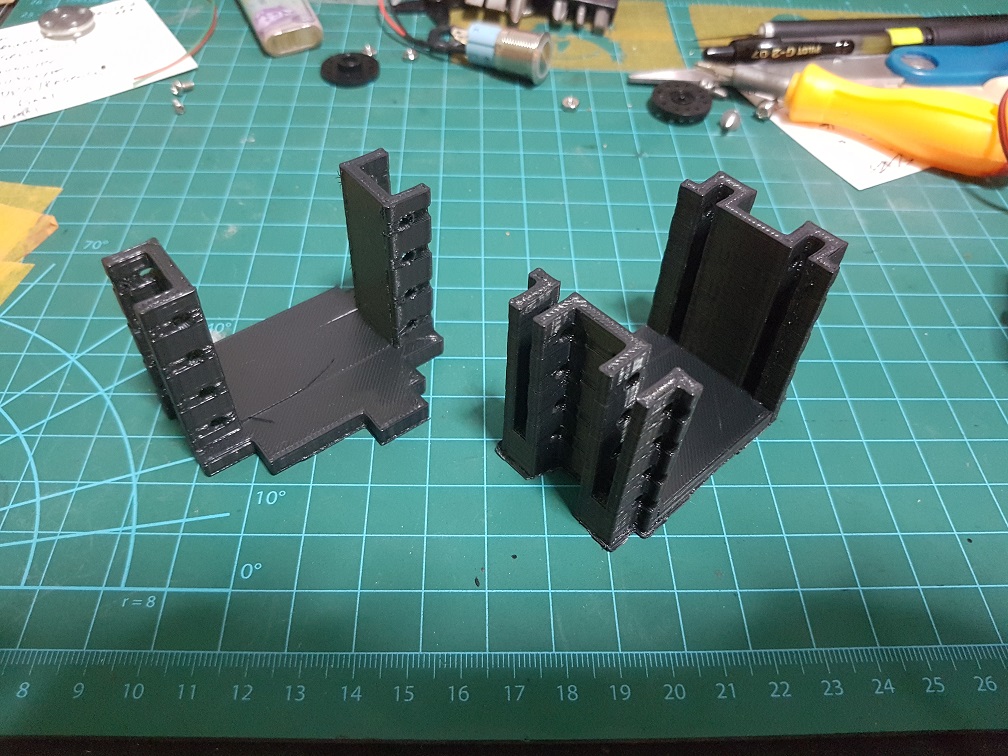

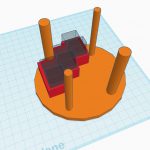

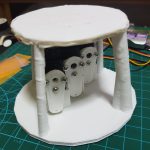

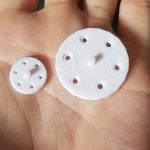

And then I printed it out in smaller scale to see how it feels.

And then I printed it out in smaller scale to see how it feels. And to check which layout should work.

And to check which layout should work. then I tested the structure of this configurations.

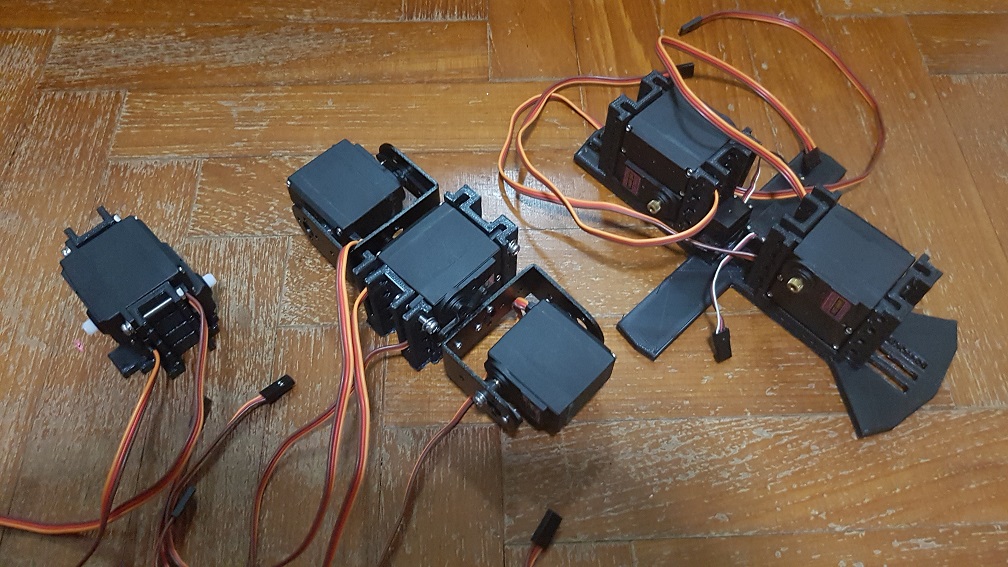

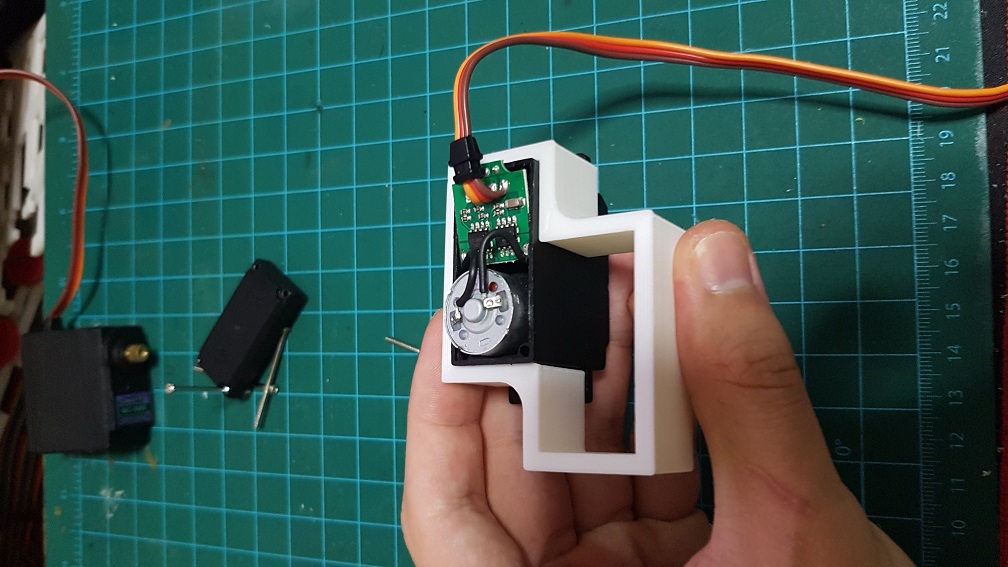

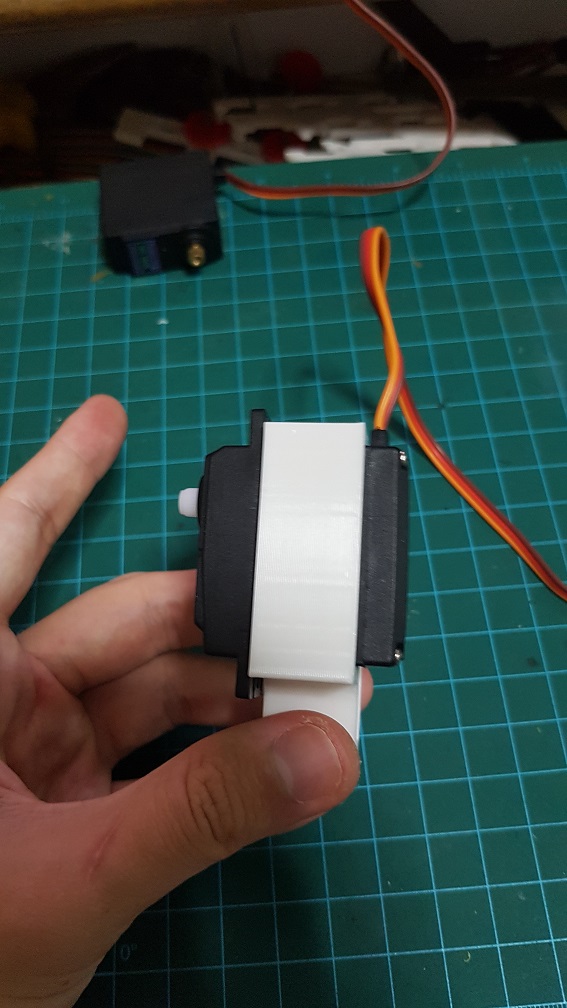

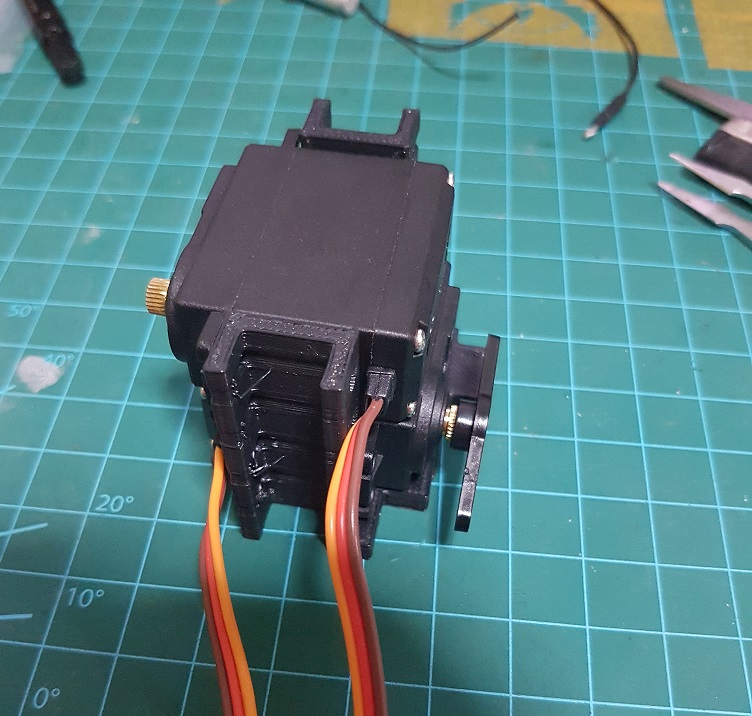

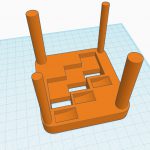

then I tested the structure of this configurations. This is with Version 5 base and version 2 Motor connector which are much shorter.

This is with Version 5 base and version 2 Motor connector which are much shorter. By combining this lever system straight into the leg.

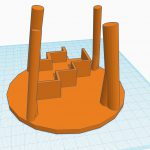

By combining this lever system straight into the leg. The 4 generation of motor connector.

The 4 generation of motor connector. This should be the mechanism I will use for the leg, I hope it works.

This should be the mechanism I will use for the leg, I hope it works.

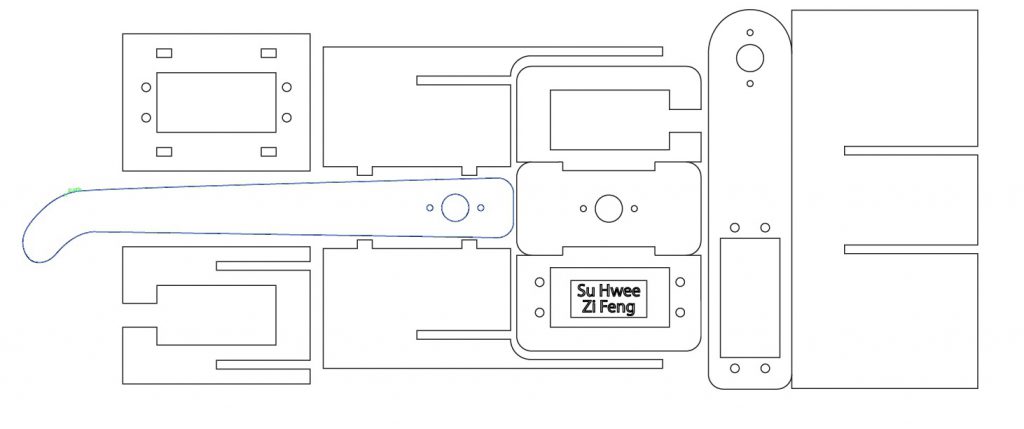

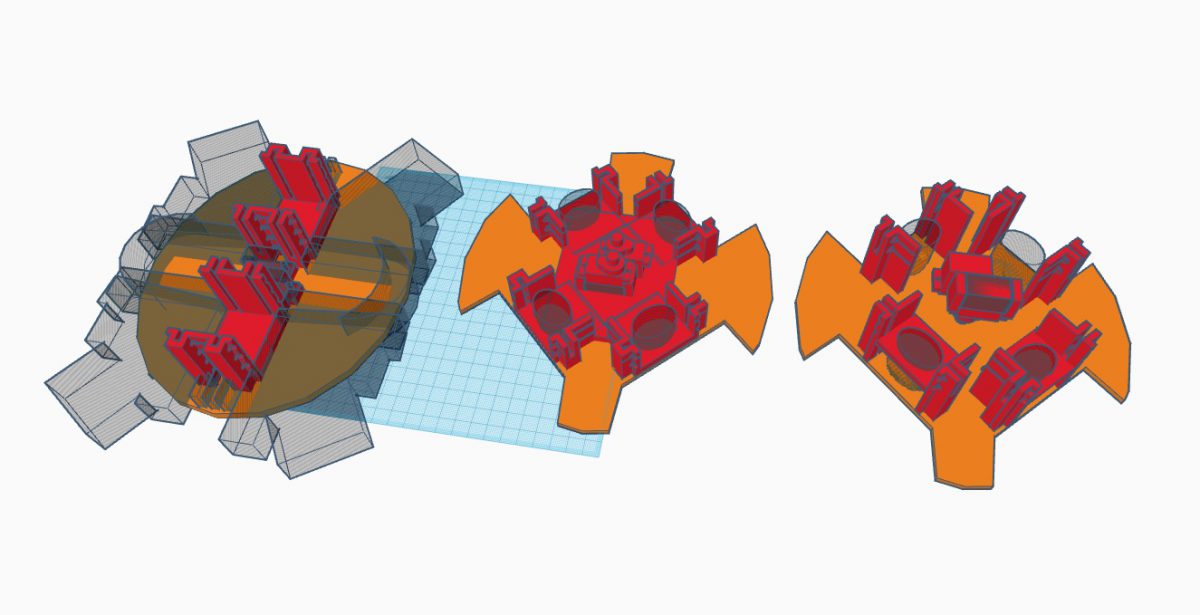

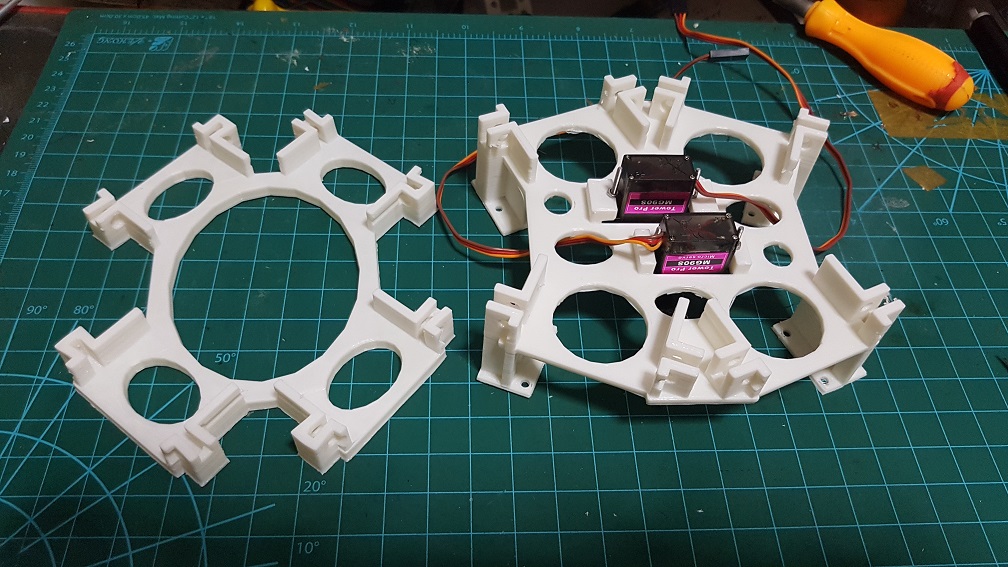

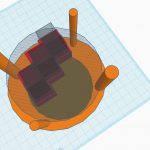

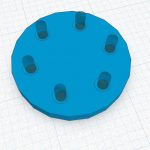

This was originally the rough full size for the turtle base, Version1, Version 2 with 2 arm motor attached, and Version 3 with no Arm motor attached.

This was originally the rough full size for the turtle base, Version1, Version 2 with 2 arm motor attached, and Version 3 with no Arm motor attached.

and since after I did more research on turtle, I realize that the bone structure of the turtle wasn’t straight and so I tilted the motors to give it an angular tilt for it to move more like a turtle.

and since after I did more research on turtle, I realize that the bone structure of the turtle wasn’t straight and so I tilted the motors to give it an angular tilt for it to move more like a turtle. I also modeled a arm motor connector and found out that this is WAAAYYY to long for it to work properly, and another problem is that there is still not enough tilt, so I changed from a 45 degree tilt to a 22.5 degree tilt.

I also modeled a arm motor connector and found out that this is WAAAYYY to long for it to work properly, and another problem is that there is still not enough tilt, so I changed from a 45 degree tilt to a 22.5 degree tilt. This is the Version 4 and Version 5 of the motor mount, I’ve decide to make it higher so to be able to turn the arm in the correct direction, I’ve also tried to add the middle servo which will control the turtle head retraction and head/tail turning.

This is the Version 4 and Version 5 of the motor mount, I’ve decide to make it higher so to be able to turn the arm in the correct direction, I’ve also tried to add the middle servo which will control the turtle head retraction and head/tail turning.

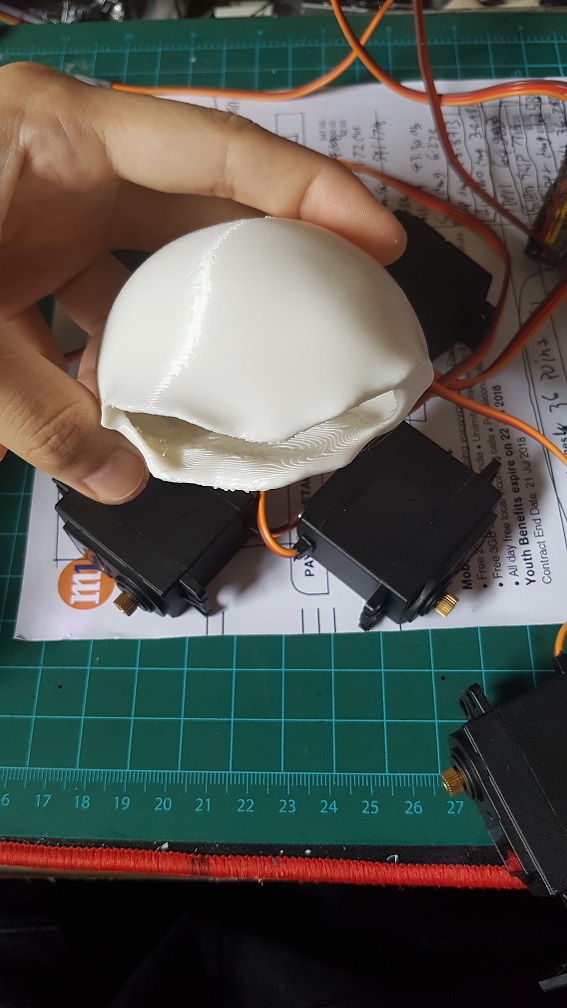

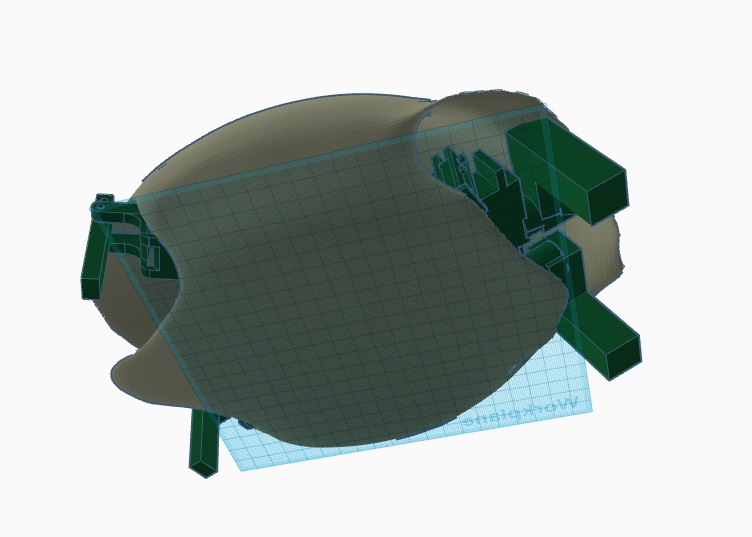

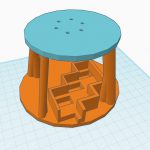

Next, I further edit the turtle shell and upscale it to see how it fits into my system, however i found many problems here like it doesnt fit well. Since I can make adjustments to the layout, I decided to use another method to do the leg mechanism.

Next, I further edit the turtle shell and upscale it to see how it fits into my system, however i found many problems here like it doesnt fit well. Since I can make adjustments to the layout, I decided to use another method to do the leg mechanism.

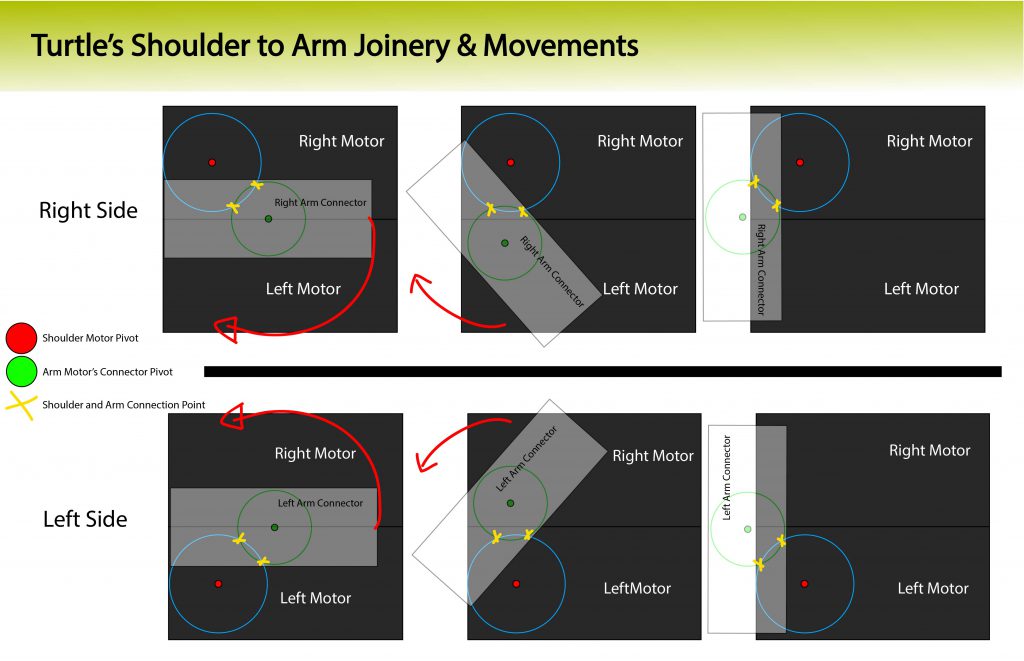

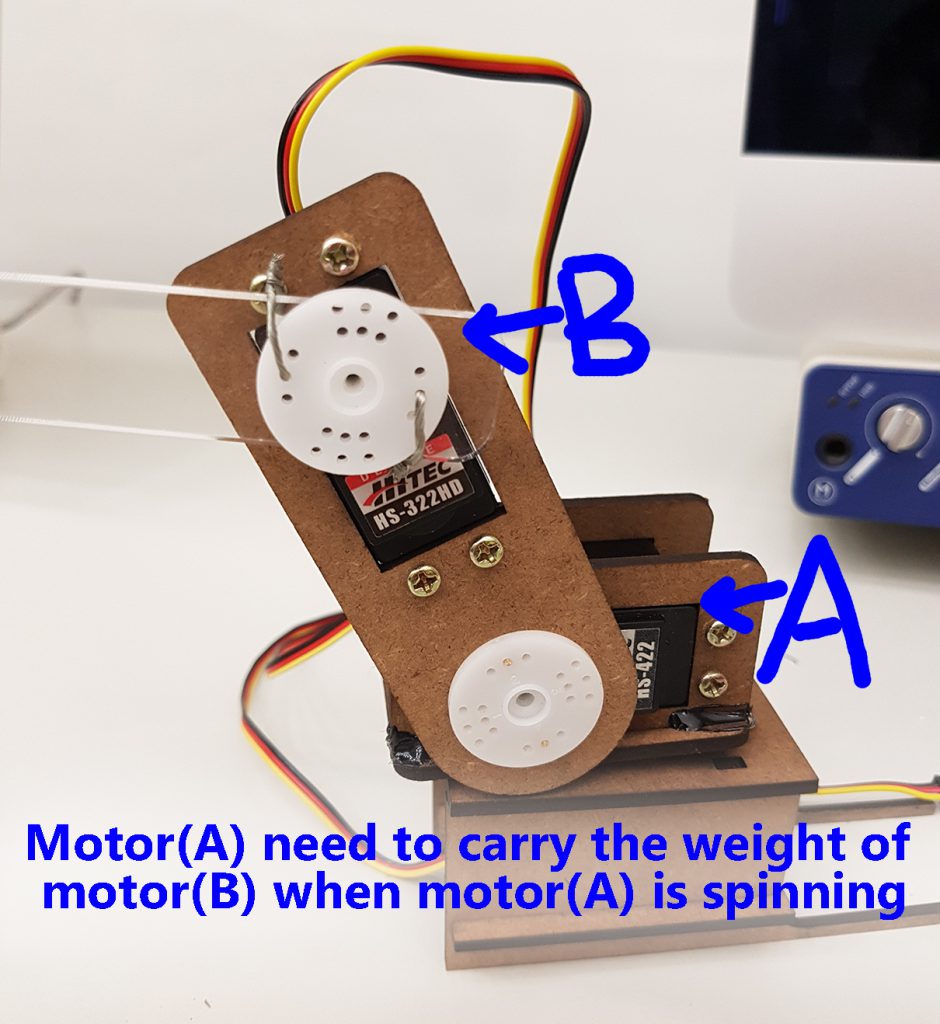

Prototype of stacking the Shoulder motors, I’ve realized that the left motor should be at the bottom and right motor should be at the top as one will spin clock wise and other will spin counter clockwise to make it the same height when their pivot are not centralized.

Prototype of stacking the Shoulder motors, I’ve realized that the left motor should be at the bottom and right motor should be at the top as one will spin clock wise and other will spin counter clockwise to make it the same height when their pivot are not centralized.

Notice how it move 1 foot at a time when turning and how it walks.

Notice how it move 1 foot at a time when turning and how it walks.

This is how a Tortoise retract its head, by bending its “neck” inwards. maybe I could emulate this.

This is how a Tortoise retract its head, by bending its “neck” inwards. maybe I could emulate this.

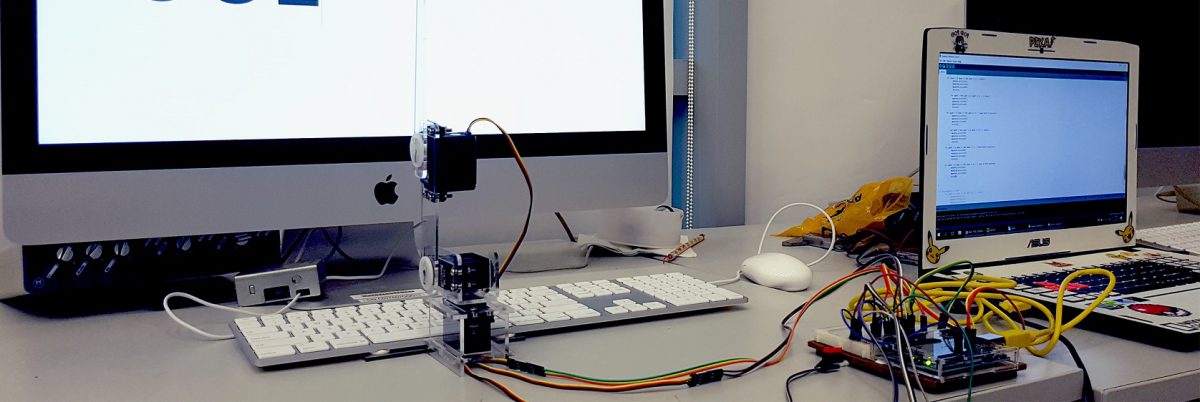

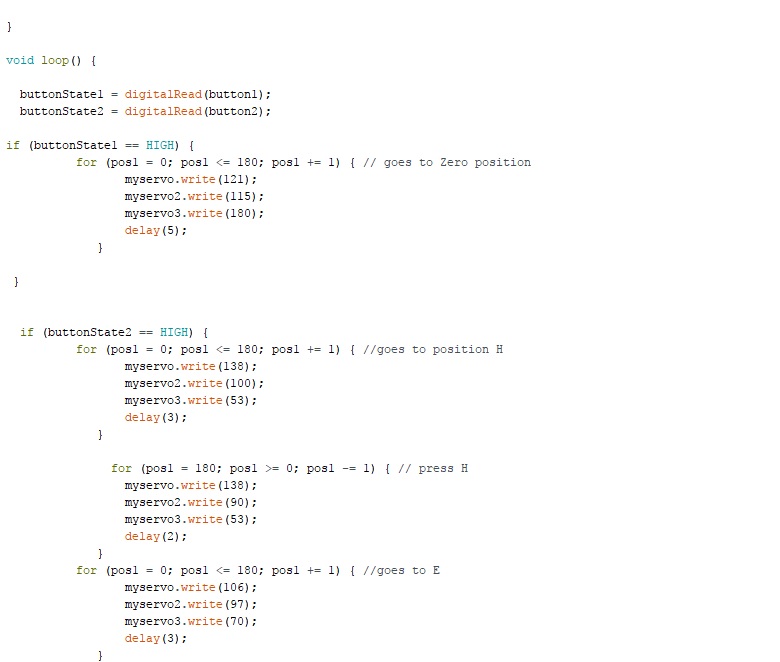

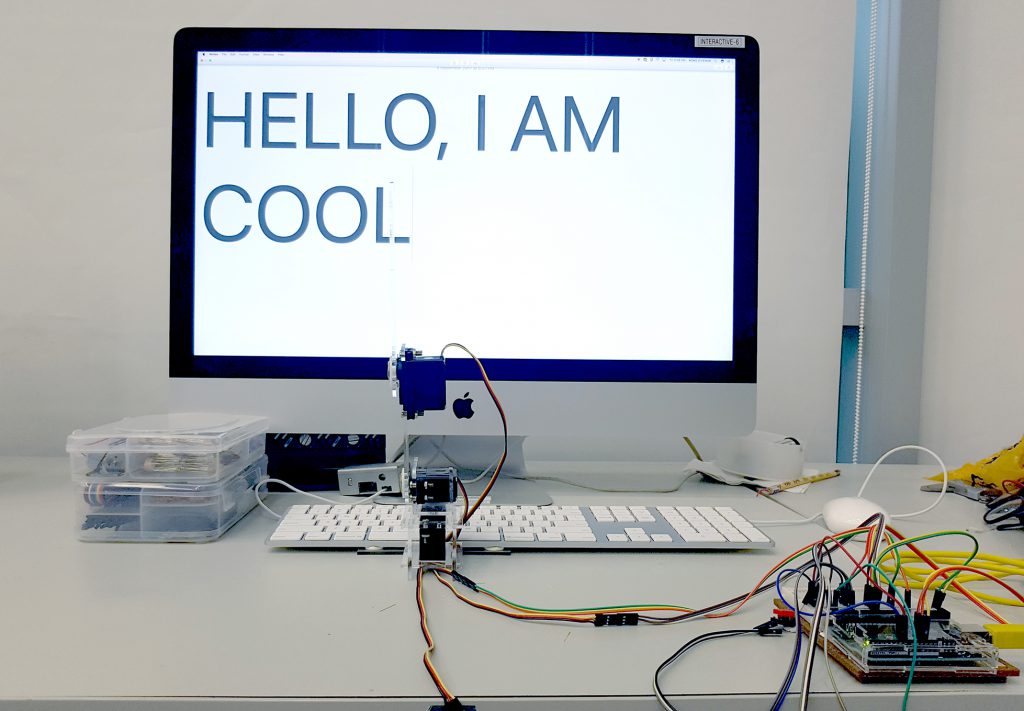

The two motor is at the base of the mechanical arm(Typebot), in comparison to our typebot,

The two motor is at the base of the mechanical arm(Typebot), in comparison to our typebot,  This Typebot system is less efficient unless the torque of the motor far exceed the weight of the system and only a when there is a short (A) to (B) distance(longer fulcrum, more torque needed to turn it)

This Typebot system is less efficient unless the torque of the motor far exceed the weight of the system and only a when there is a short (A) to (B) distance(longer fulcrum, more torque needed to turn it)

Chris Trying to interact with Nadine.

Chris Trying to interact with Nadine. Photo credit to Isaac Chu

Photo credit to Isaac Chu

One spring in the middle was too flimsy until we added strings

One spring in the middle was too flimsy until we added strings emulation of 3 motors and movements, We were impressed.

emulation of 3 motors and movements, We were impressed. And we fixed everything together and tied it with fishing lines.

And we fixed everything together and tied it with fishing lines.